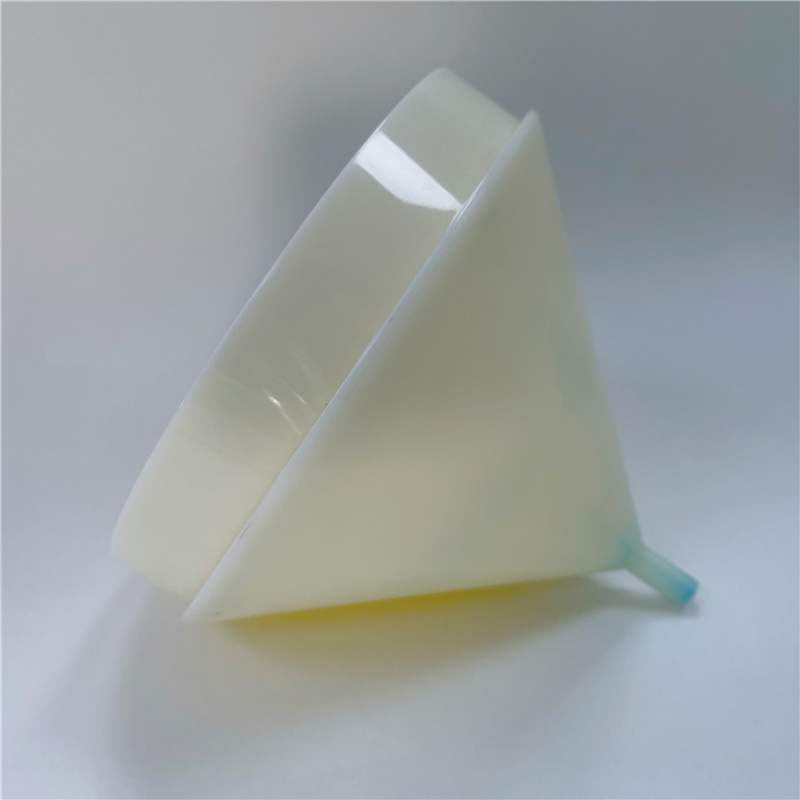

Europe style for Brass Stamping Copper Mold - Injection Plastic Mould Case – Ruicheng

Product Details

Europe style for Brass Stamping Copper Mold - Injection Plastic Mould Case – Ruicheng Detail:

Before Mould-Making:

After having the design 3D drawings, we will make a thorough analysis to evaluate its mould-making method based on your requirements, to find if the design needs any improvement for better production to avoid shrinkage/undercut/etc problems.

The following information is requested before mould-making:

1. Parts Design Drawing, better in 3D drawing, if not, 1pcs sample is acceptable;

2. Specified plastic material, or we can suggest the suitable material after knowing its usage conditions.

3. Estimate Production quantities

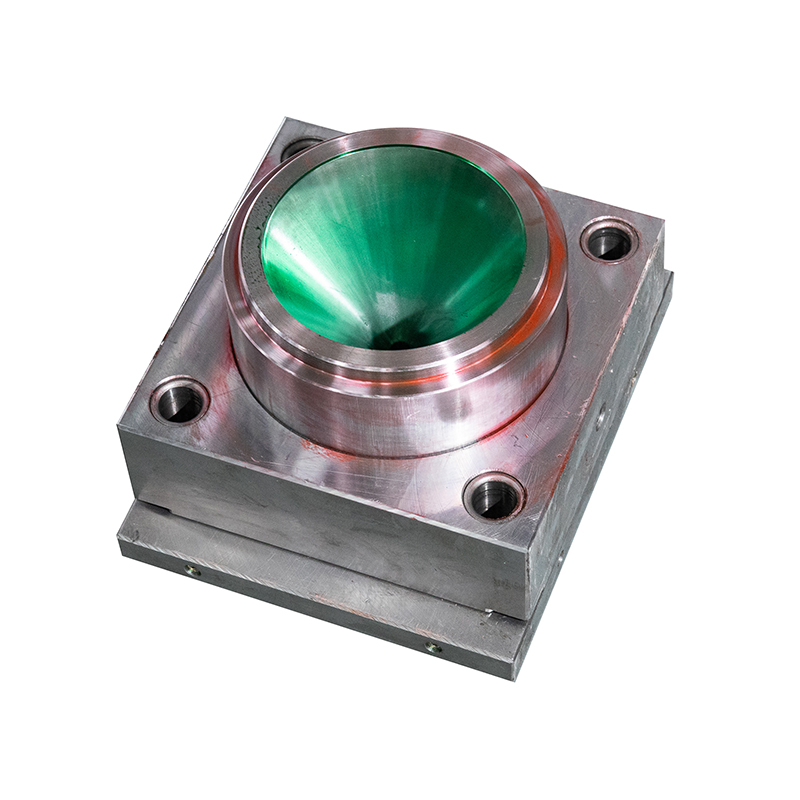

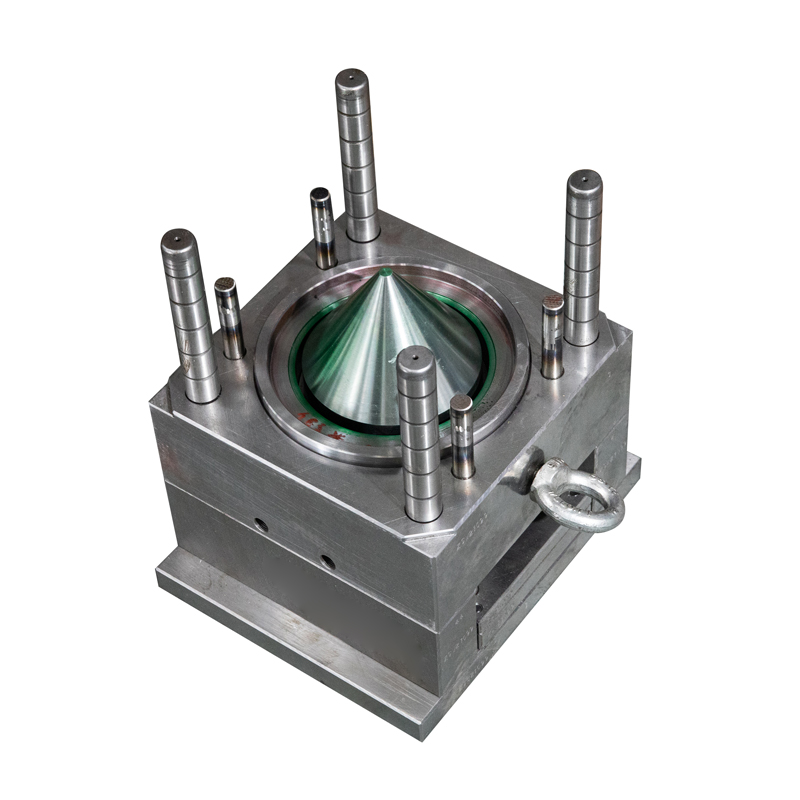

Mould-Making Process:

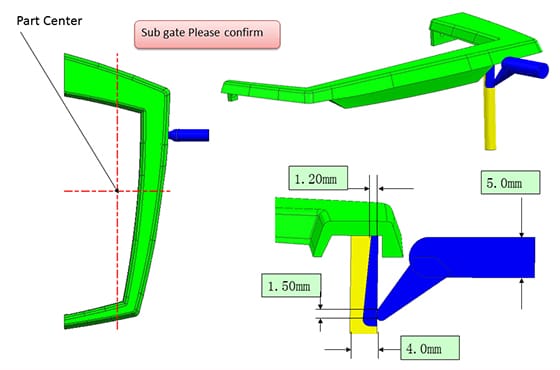

1. Mould DFM Analysis

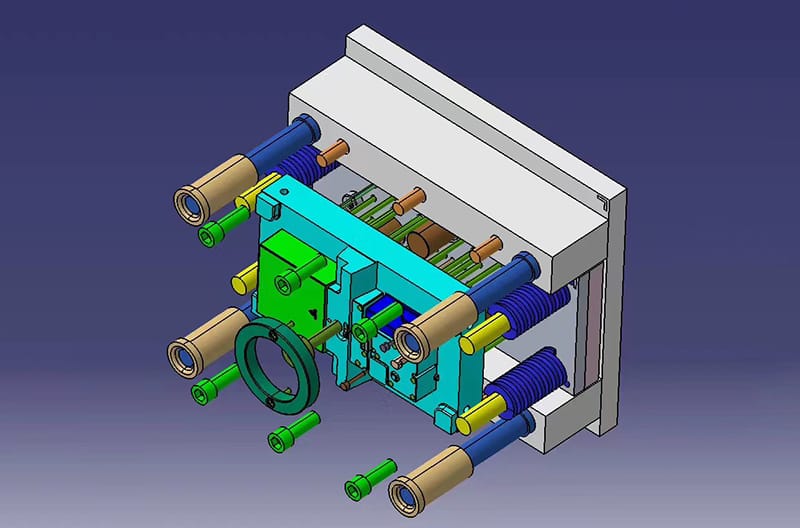

2. Mould Design

3. Mould Material Preparation

4. CNC machining

5. EDM Machining

6. Grinding&Drilling Machining

7. wire EDM maching

8. mould aftet treatment

9. Mould Assembly

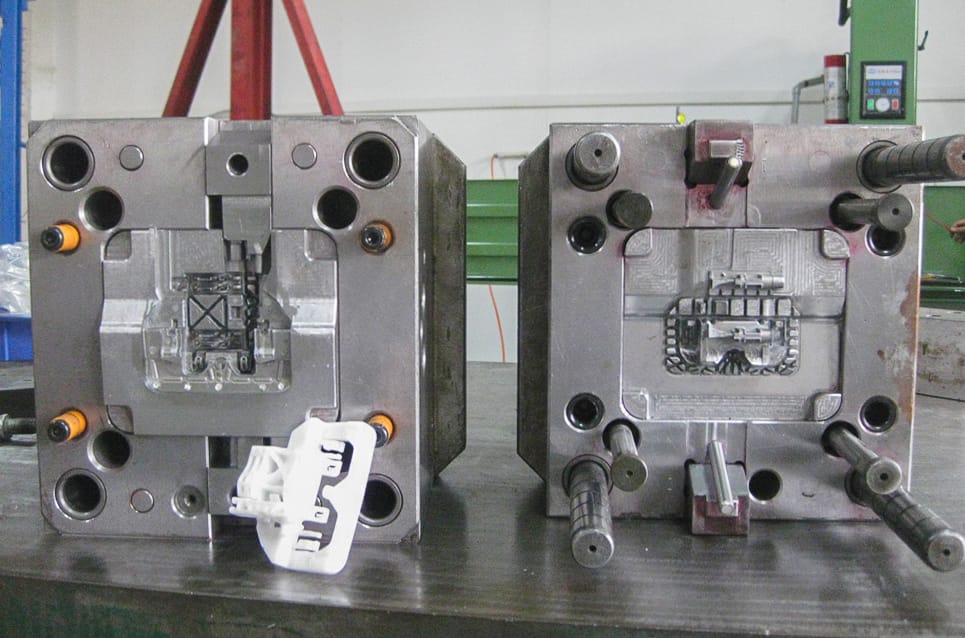

After mould is finished:

1. Mould trial

2. Sample Approval

3. Injection Production

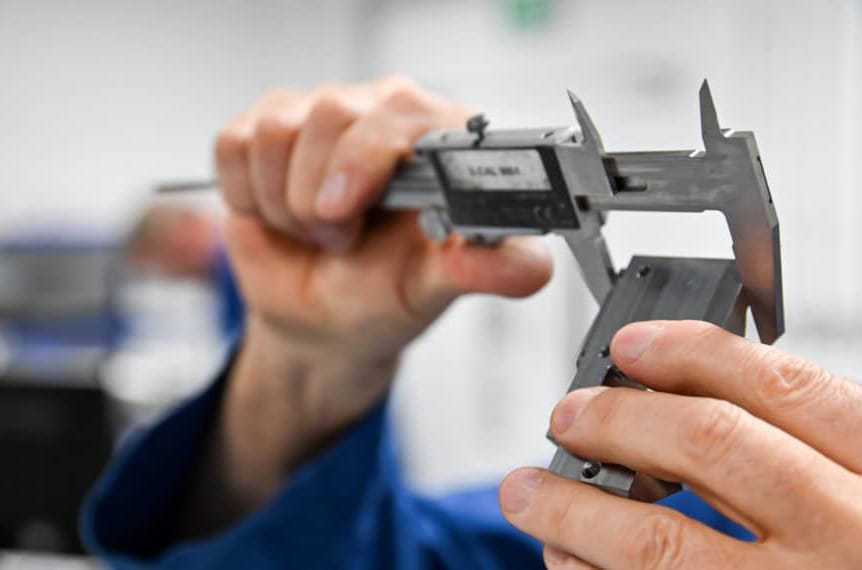

4. Prodcuts Inspection

5. Ready for Shipment

6. Mould Storage&Maintenance

FAQ

1, Q: How do I know if injection molding is the suitable and right process for my product?

A: The part’s geometry, the quantity need, project budget and the application the part is being used for are the factors to decide this.

2, Q: How long does it take to make an injection mold?

A: 4-8 weeks on average, depending on the mold’s complexity and size.

3, Q: Do you offer short or long production runs?

A: We offer both high and low volume production runs for customized products at any scale.

4, Q: Who own the mold?

A: Who pay the mold price who has the right to own it. As a supplier, we will help to store and maintain the finished mold safe until its shoting life comes to the end.

5,Q: How should I get started?

A: Just send us your files, we accept a variety of CAD formats and can even start to work from sketches, models or pre-existing parts.

To learn more about our services or how you can get started on your own project, contact our team today.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Europe style for Brass Stamping Copper Mold - Injection Plastic Mould Case – Ruicheng , The product will supply to all over the world, such as: Uruguay, Swedish, Jamaica, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!