Factory directly Punching Die - Injection Plastic Mould Case – Ruicheng

Product Details

Factory directly Punching Die - Injection Plastic Mould Case – Ruicheng Detail:

Before Mould-Making:

After having the design 3D drawings, we will make a thorough analysis to evaluate its mould-making method based on your requirements, to find if the design needs any improvement for better production to avoid shrinkage/undercut/etc problems.

The following information is requested before mould-making:

1. Parts Design Drawing, better in 3D drawing, if not, 1pcs sample is acceptable;

2. Specified plastic material, or we can suggest the suitable material after knowing its usage conditions.

3. Estimate Production quantities

Mould-Making Process:

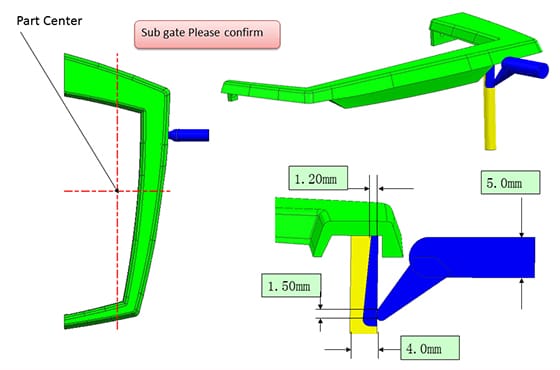

1. Mould DFM Analysis

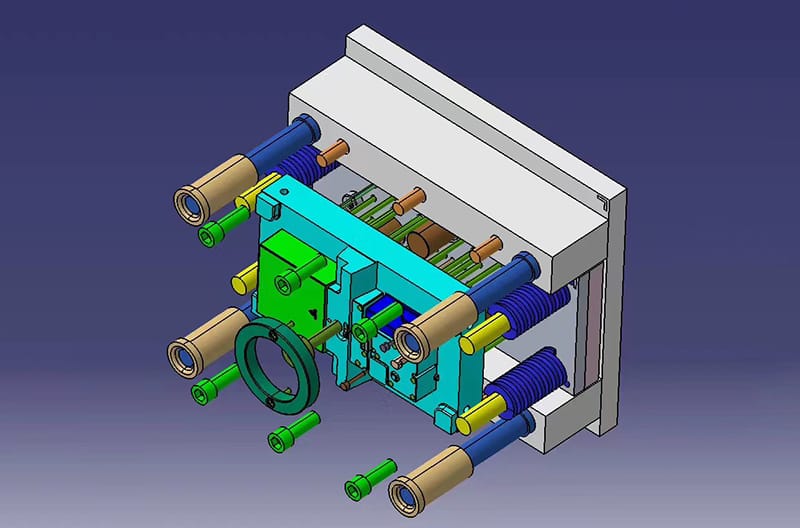

2. Mould Design

3. Mould Material Preparation

4. CNC machining

5. EDM Machining

6. Grinding&Drilling Machining

7. wire EDM maching

8. mould aftet treatment

9. Mould Assembly

After mould is finished:

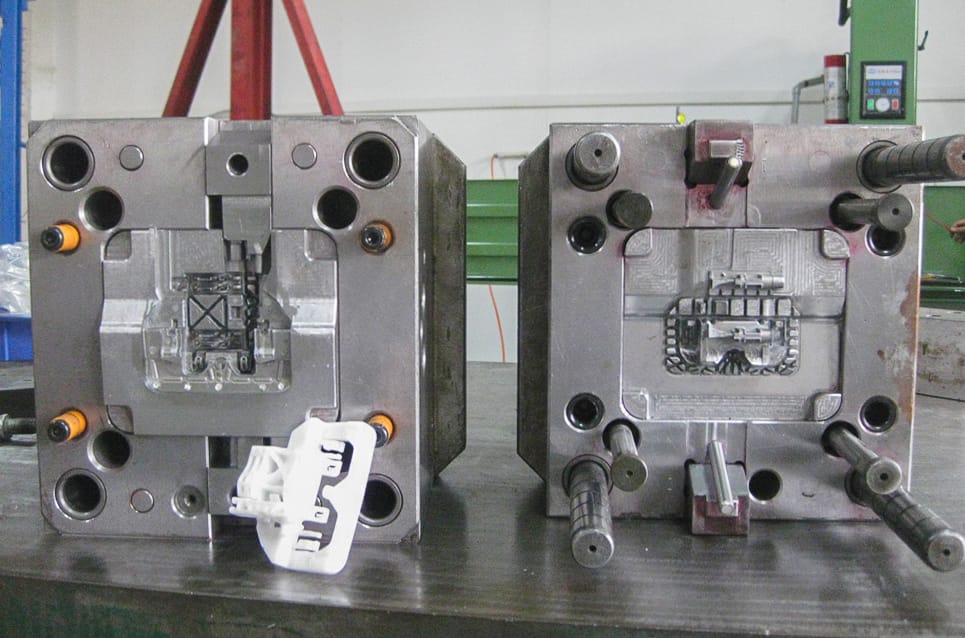

1. Mould trial

2. Sample Approval

3. Injection Production

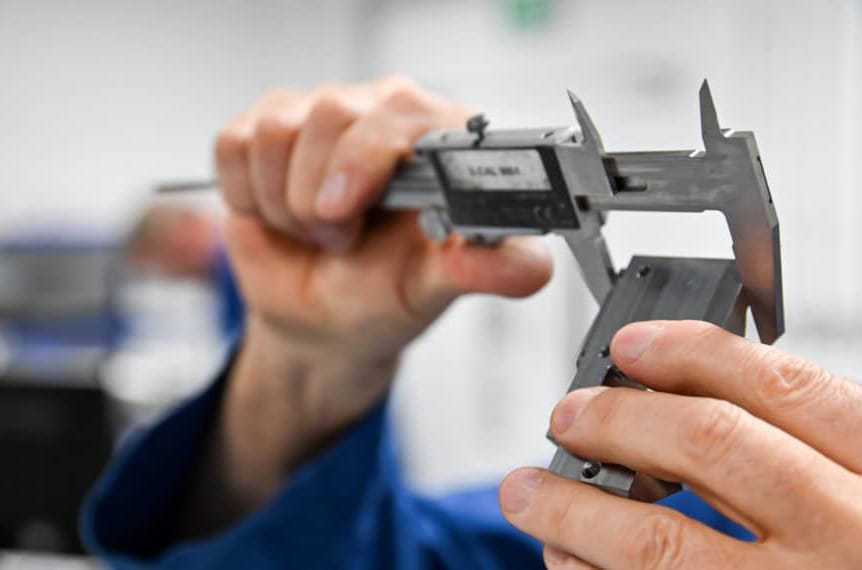

4. Prodcuts Inspection

5. Ready for Shipment

6. Mould Storage&Maintenance

FAQ

1, Q: How do I know if injection molding is the suitable and right process for my product?

A: The part’s geometry, the quantity need, project budget and the application the part is being used for are the factors to decide this.

2, Q: How long does it take to make an injection mold?

A: 4-8 weeks on average, depending on the mold’s complexity and size.

3, Q: Do you offer short or long production runs?

A: We offer both high and low volume production runs for customized products at any scale.

4, Q: Who own the mold?

A: Who pay the mold price who has the right to own it. As a supplier, we will help to store and maintain the finished mold safe until its shoting life comes to the end.

5,Q: How should I get started?

A: Just send us your files, we accept a variety of CAD formats and can even start to work from sketches, models or pre-existing parts.

To learn more about our services or how you can get started on your own project, contact our team today.

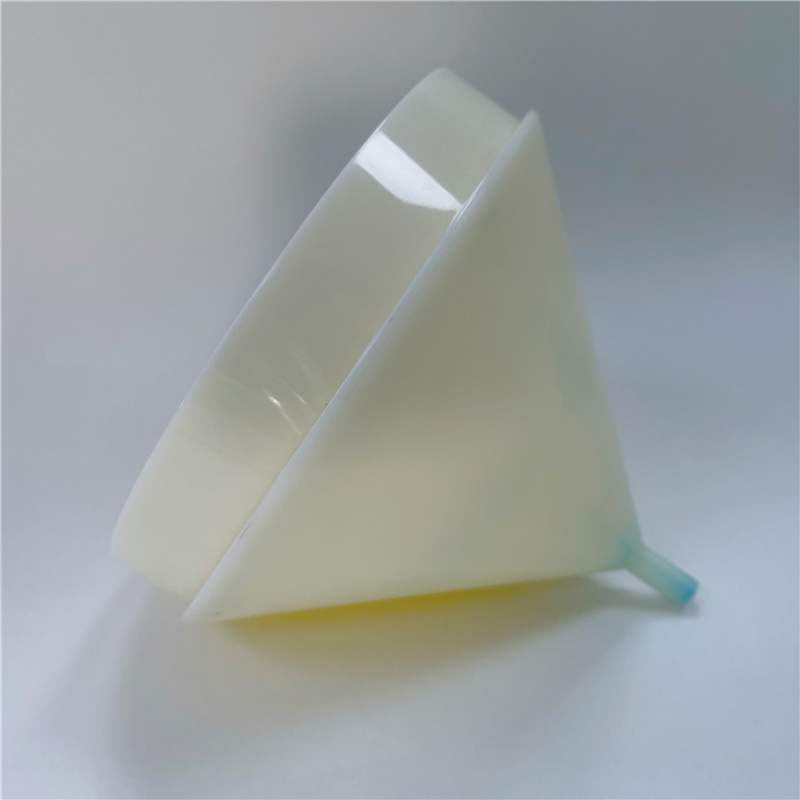

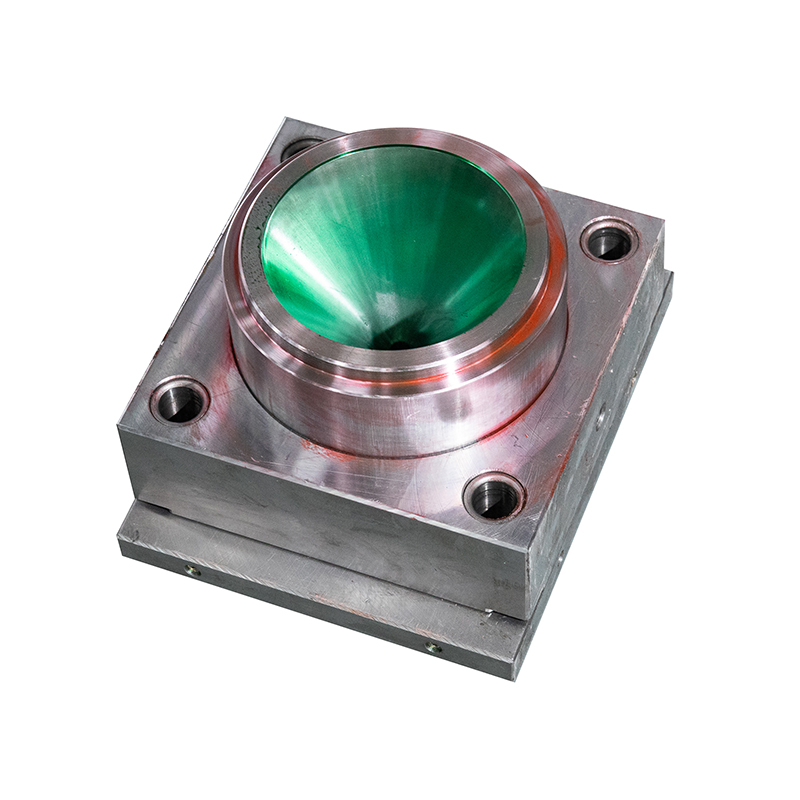

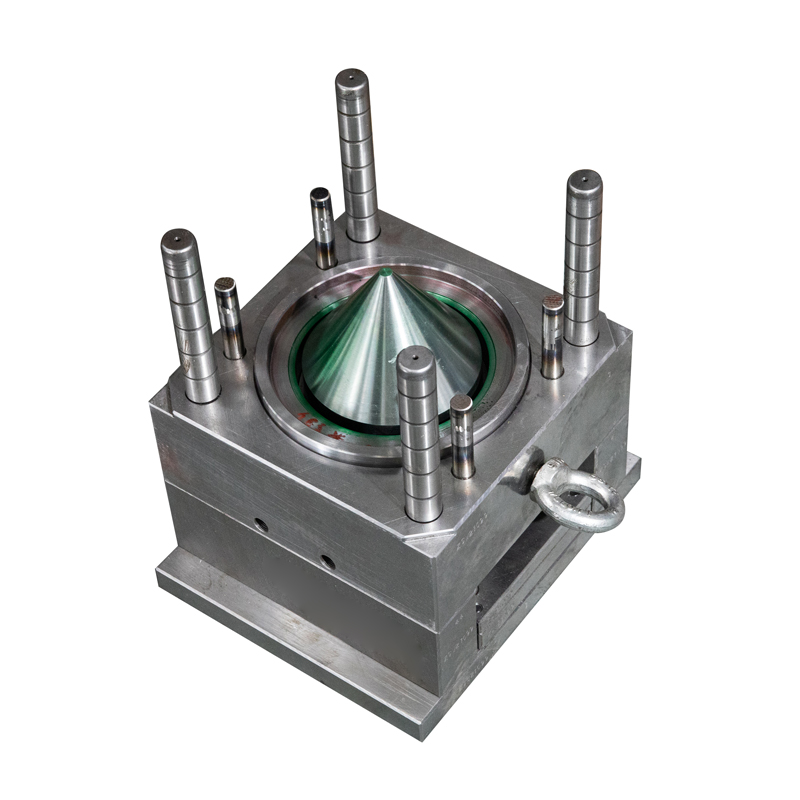

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Factory directly Punching Die - Injection Plastic Mould Case – Ruicheng , The product will supply to all over the world, such as: Nepal, Bahrain, Lahore, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.