Factory Outlets Die Casting Car Mold - Plastic Injection Parts – Ruicheng

Product Details

Factory Outlets Die Casting Car Mold - Plastic Injection Parts – Ruicheng Detail:

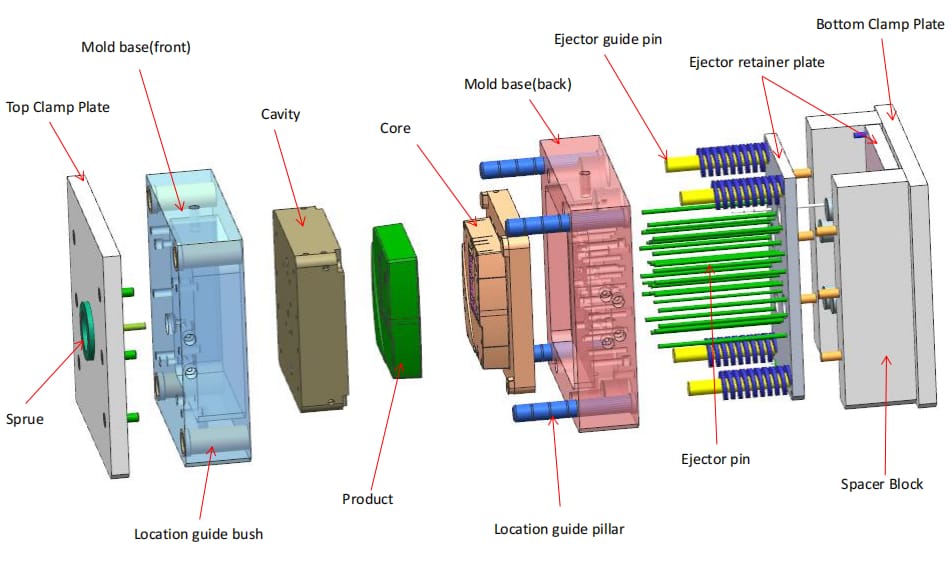

Project Analysis:

After receiving 3d drawings and requirements from customers, our engineer team will evaluate its structures and dimensions to discuss and consider how to design the mold ( such as the injection gate, pins, draft angle etc.)

Production Process:

1. Clamping:

The tool closes, signifying the start of the injection molding cycle.

2. Injection:

The polymer granules are first dried and placed in the hopper, then they are fed into the barrel, where they are simultaneously heated, mixed and moved towards the mold by a variable pitch screw. The geometry of the screw and the barrel are optimized to help build up the pressure to the correct levels and melt the material.

3. Cooling:

After the tool cavity is filled, the resin must be allowed to cool. Water is cycled through the tool to maintain a consistent temperature while the material hardens.

4. Ejection

As the material cools down, it re-solidifies and takes the shape of the mold. Finally, the mold opens and the solid part is pushed out by the ejector pins. The mold then closes and the process repeats.

5. Package

The finished products will be packed by using plastic bag and put into cartons. Special packaging requirements, can also be customized according to the needs of customers .So that every product will be delivered in the good condition.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Factory Outlets Die Casting Car Mold - Plastic Injection Parts – Ruicheng , The product will supply to all over the world, such as: Amsterdam, Ethiopia, panama, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.