Hot sale High Precision Metal Progressive Die - Customized Aluminum Die Casting Housing – Ruicheng

Product Details

Hot sale High Precision Metal Progressive Die - Customized Aluminum Die Casting Housing – Ruicheng Detail:

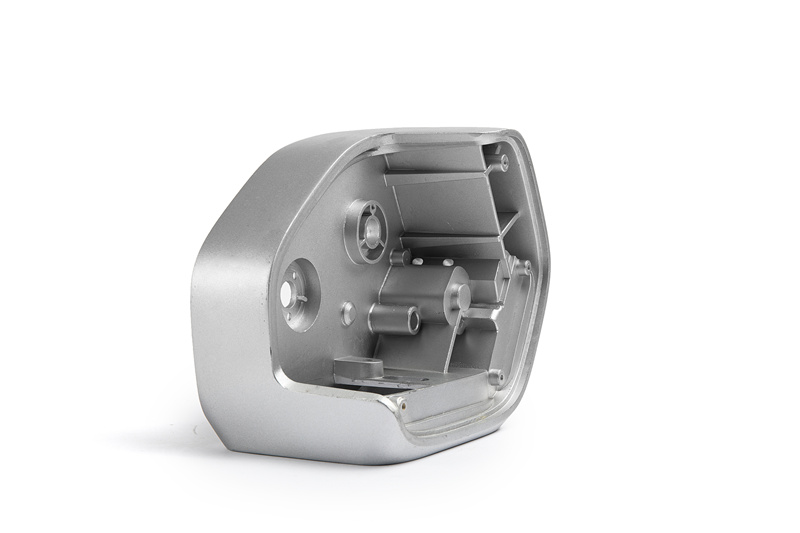

Why Aluminum Die Casting?

The most significant advantage of aluminum die casting compared to other processes like machining, or sheet metal forming is that aluminum can create intricate 3D designs very efficiently at a lower cost. Because of this, manufacturers are able to order customized castings that are ideal for their production needs. Aluminum die castings can turn molten metal into a near-net shape part in seconds, so machining or other operations can be almost eliminated.

Die Casting Process

1. Drawing Design:

DFM is one of the best methods followed by Xiamen Ruicheng engineers to optimize the manufacturability of castings while retaining functionality. Xiamen Ruicheng has a team of more than ten professional engineers who will provide effective suggestions on material structure and find a balance between design, cost and part performance.

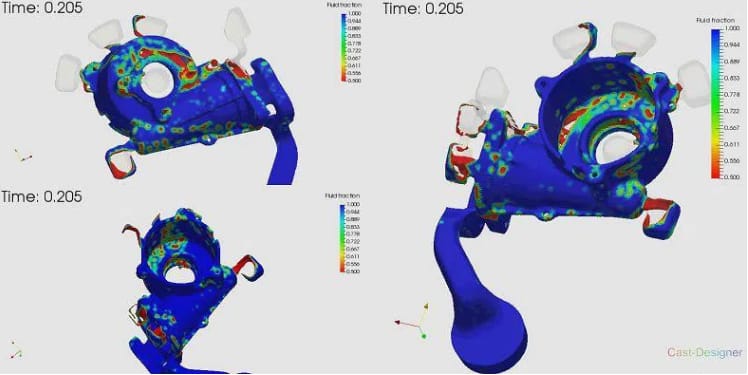

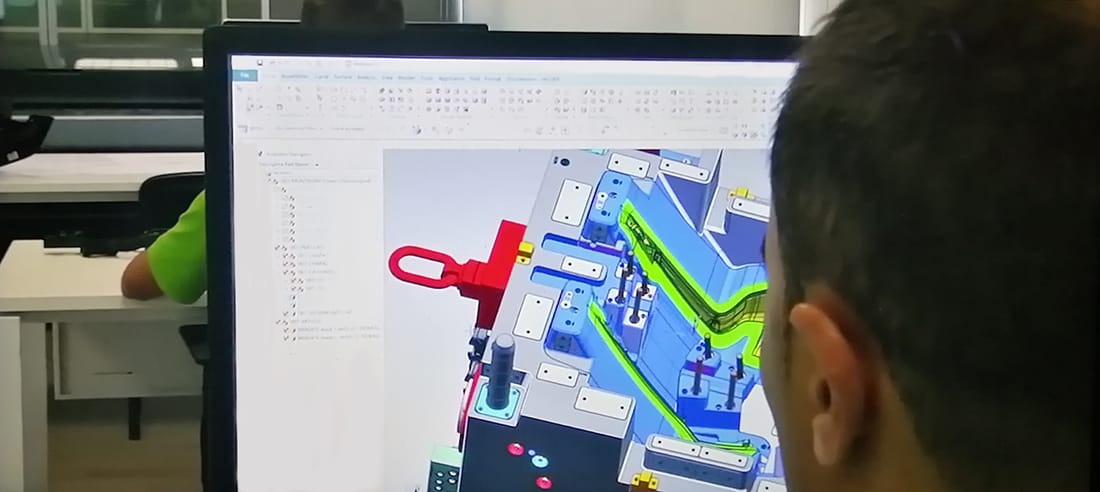

2. Mold Design:

The mold stage simulates the filling flow and solidification process, predicts the defects that will appear in the die casting, and predicts the microscopic metal and mechanical properties, and the strength of the mold ejector pin. Optimize runner and gate design, improve production process parameters, reduce R&D and production costs, and improve casting product quality.

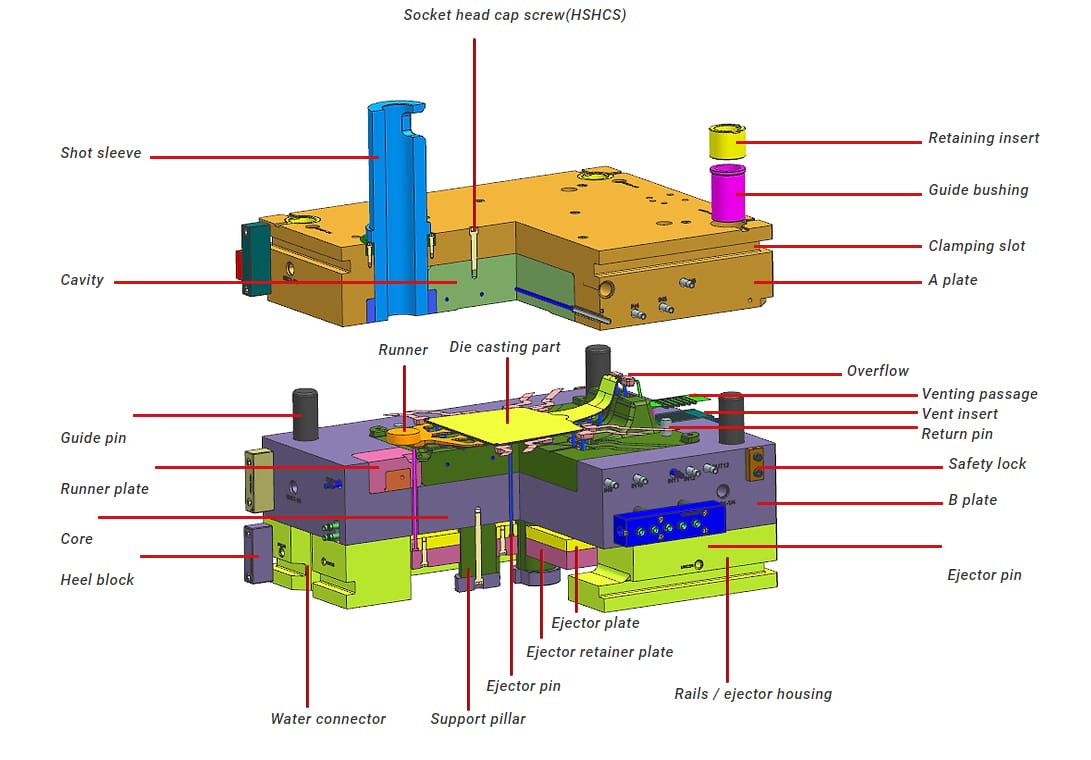

3. Mold Manufacturing:

we offer two different types of tooling processes: multi-slide and conventional. Each has their own unique benefits and our skilled engineers can help decide which tooling is best for each project. The process of manufacturing the components according to the mold design drawing, using mechanical cutting, spark machining, surface treatment and heat treatment, and finally assembling all parts into a mold according to the design drawing.

4.Die-Cast Ability:

Xiamen Ruicheng is one of the few companies with the ability to expand the casting range, with die casting machines of 58-3000 tons of different tonnage. It can produce parts weighing 5g-35kg. The independent furnace of each die casting machine enables us to provide a variety of aluminum, zinc, magnesium and their alloys to meet the unique needs of customers.

5.Surface Treatment Ability:

With more than 10 years experience in Die Casting manufacturing ,Xiamen Ruicheng can complete the physical surface treatment, spray painting, powder coating, anodizing and chrome plating, especially the anodizing. There are few suppliers in China who can Anode Oxidation die castings very well.

6. Assembly Ability:

Xiamen Ruicheng provides customers with a variety of mechanical assembly and sub-assembly services. We have extensive experience in assembling hardware, including screws, screws, bolts, pins, inserts, gaskets and O-rings, and pressure seal testing to ensure product functionality .

7. Quality Inspection System:

Xiamen Ruicheng pays special attention to the quality control of the mass production process and has established a complete quality inspection process and system. Five tools are commonly used: PPAP, APQP, PFMEA, SPC, and MSA. All products are fully inspected or constructed in accordance with the standards. Testing equipment includes: spectrometer, stretching Testing machine, CMM three-coordinate, pass-stop gauge, parallel gauge, various calipers, etc., to achieve the control ability of the quality system.

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Hot sale High Precision Metal Progressive Die - Customized Aluminum Die Casting Housing – Ruicheng , The product will supply to all over the world, such as: Madrid, Jeddah, India, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

A good manufacturers, we have cooperated twice, good quality and good service attitude.