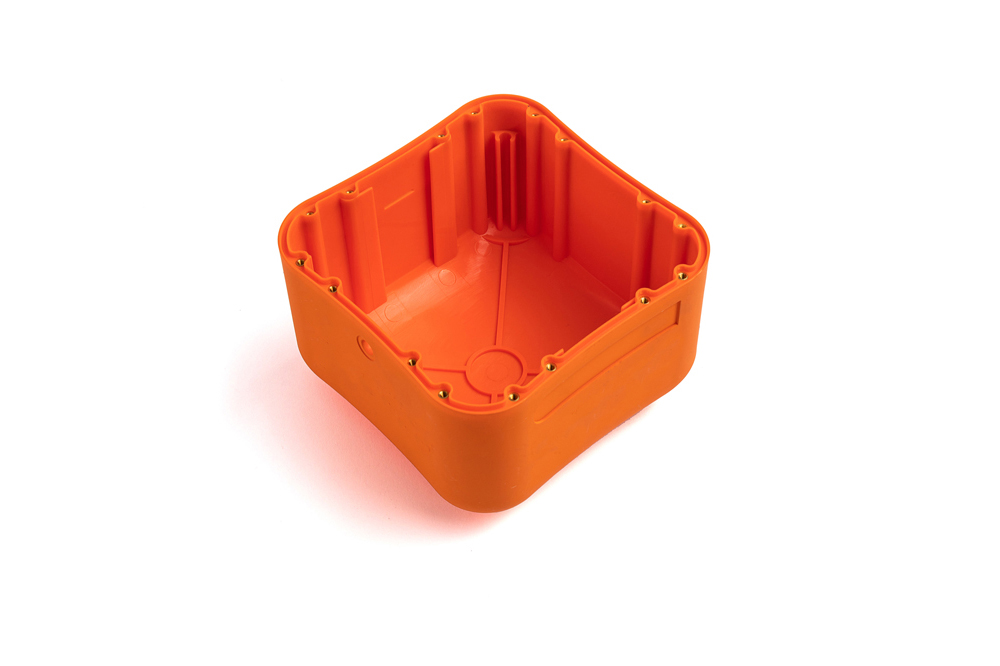

Lamp Housing

Product Details

OVERVIEW:Customized plastic injection parts with good waterproof and UV resistance, which makes this product function well in outdoor environment.

GUARANTEE: A good combination of practicality and aesthetics, making our customers satisfied with our work.

TECHNICAL: Injection Mould

Injection plastics Applications & Industries

Xiamen Ruicheng works with a variety of industries to provide injection molding services to help create, design, and mold custom applications and parts. Some of the markets we serve are:

Automotive plastic parts

Industrial plastic parts

Sports plastic parts

Medical plastic parts

Household Appliance

Consumer plastic parts

Our Injection Molding Capabilities

→Wide range of the best injection molding equipment from 100 tonnages to 1400 tonnages;

→Semi-Automated Work Cells: servo robotics, vision systems;

→Complete Quality Control & Inspection;

→Processing expertise with a wide range of plastic injection materials;

→Experienced plastic injection engineering team provides solutions according to client’s requirements.

Frequently Asked Questions

3D drawing and its requirement like material, quantity and surface finish.

Our MOQ is from 500 to 2000, which depends on the product’s size.

It is always the rule that who pays the injection molds who own them. We are just the manufacturer and keeper on them

The SPI (Society of the Plastics Industry) classifies injection molds based on their life expectancy:

Class 101 – Life expectancy of +1,000,000 cycles. These are the most expensive injection molds.

Class 102 – Life expectancy not to exceed 1,000,000 cycles

Class 103 – Life expectancy under 500,000 cycles

Class 104 – Life expectancy less than 100,000 cycles

Class 105 – Life expectancy less than 500. This classification is for prototype molds and these molds are the least expensive.

We usually provide advice and quotations according to the customer's life expectancy requirements

Most material has its application specific. If you don't have a material selected for your application, we can help and offer some guidance. Often several materials can be sampled but the customer has final approval before proceeding.

If you would like to check our stock plastic injection samples to know our quality, it is free to offer the material/surface finish sample you want by charging only its freight cost.

For the injection molds you pay to make, we will offer free testing samples after mould is finished

We have a strict and full inspection flow by having advanced inspection jigs/machines and one professional QC team. The finished products must pass this flow to get its approval to be shipped

Talk to us Now to enjoy free consultation &free DFM on your new project.

CONTACT US

NEED HELP?

A good combination of practicality and aesthetics, making our customers satisfied with our work.