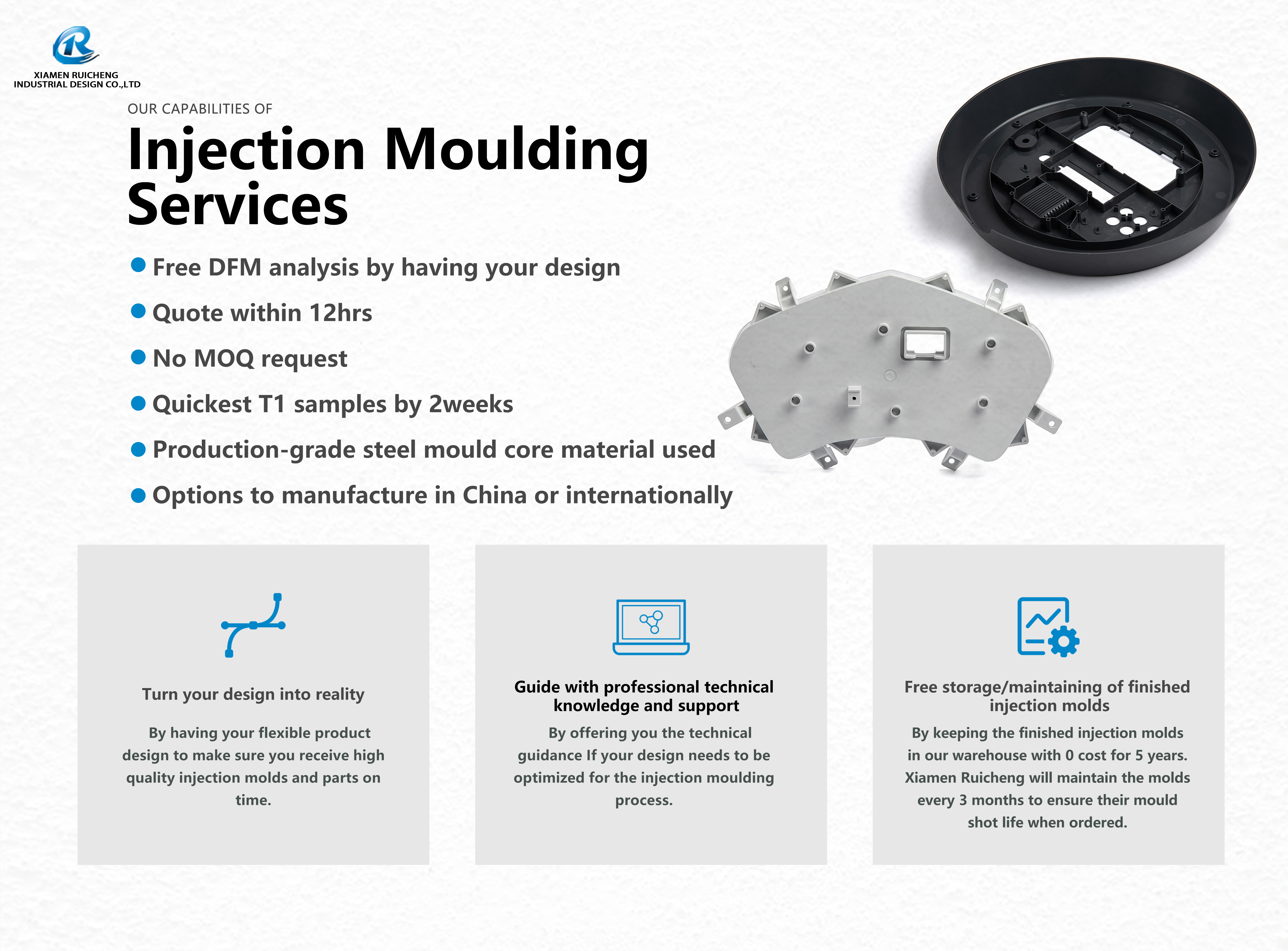

Let’s Talk About What We Can Make, Build, Scale Together.

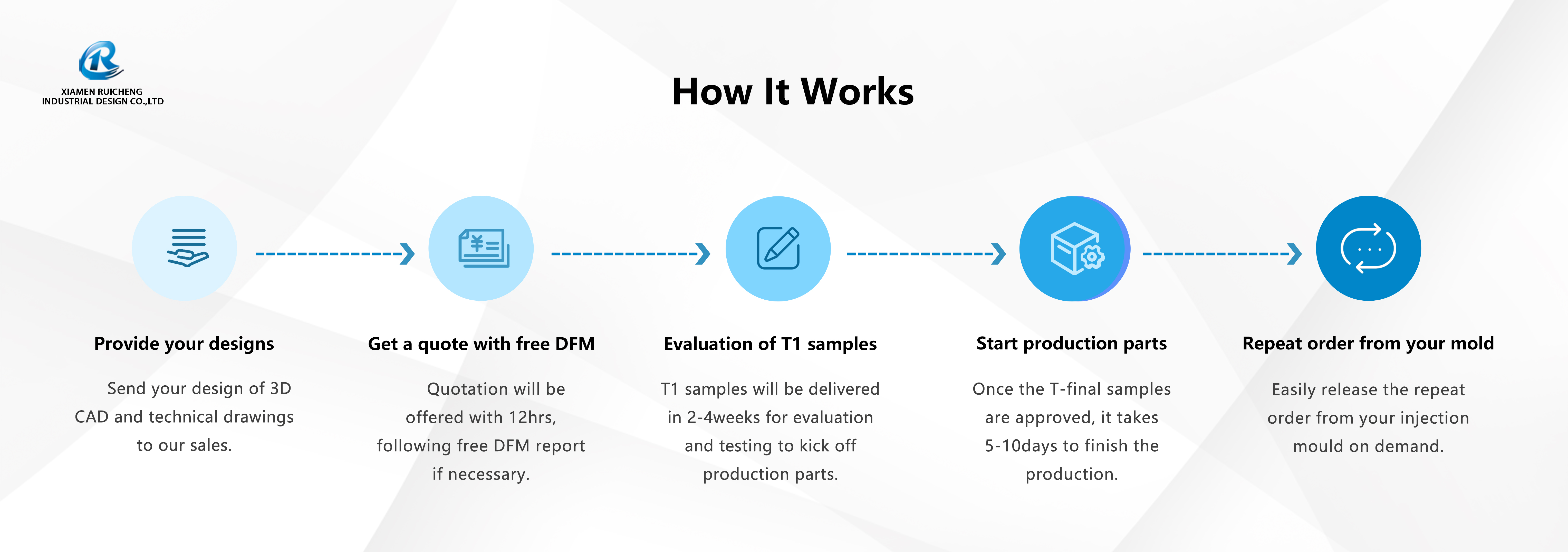

Before every plastic injection mould cutting, it is necessary to do its DFM analysis to make sure it can be injected perfect by finding whether there is any design improvements needed. Success is defined by outcome,the video is the example work that mattered that can help you have a understanding on what exact the process is. Contact us now to get a free DFM report if you are developing any new product.

Injection Molding Processes

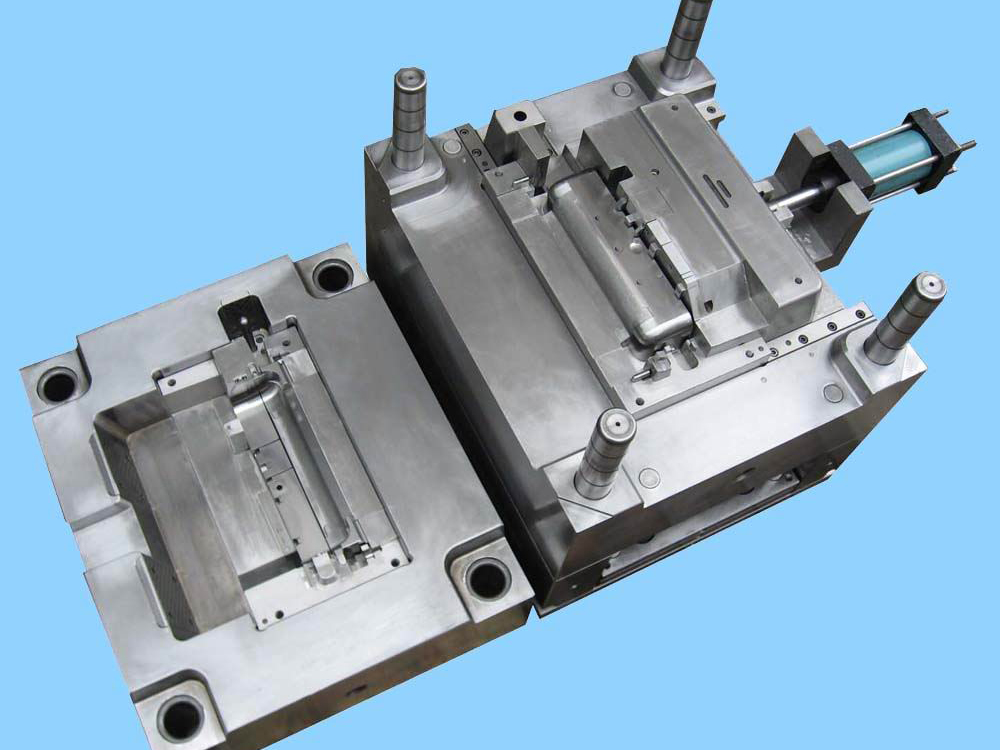

Rapid injection mold

Rapid injection mould with quick lead times, ideal for prototyping and small quantity production that is for design validation to bridge production.

Overmolding

The overmolding process let you combine multiple materials into one part. One material, usually a thermoplastic elastomer (TPE/TPV/TPU) is molded onto a second material which is often a rigid plastic. Or to overmould metal inserts inside the plastics.

Two-color mold

Two-color injection molding is a manufacturing process used when referring to mold two materials/colors into one plastic part,which is a technology blends two materials or two different colors into one ending plastic part by using 2k injection molding machine.

Mass production injection mold

Mass production Injection molding is a manufacturing process that involves injecting molten material into a mold cavity by using production grade steel mould material that can make its shot life to be more than 200,000cycles.

Injection Molding Finishes

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A2 SPI-A3 |

SPI-B1 SPI-B2 SPI-B3 |

SPI-C1 SPI-C2 SPI-C3 |

MT (Moldtech) VDI (Verein Deutscher Ingenieure) |

Injection Molding Materials

ABS

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic that is created using emulsion.With its Strong, flexible, low mold shrinkage (tight tolerances), chemical resistance, electroplating capability, naturally opaque, low/medium cost.

Common applications:Automotive (consoles, panels, trim, vents), boxes, gauges, housings and toys.

Acetal/POM (Delrin)

POM is a low-friction, lightweight thermoplastic that is strong and rigid with excellent fatigue resistance, excellent creep resistance, chemical resistance and moisture resistance in naturally opaque white with low/medium cost.

Common applications: Bearings, cams, gears, handles, rollers, rotors, slide guides, valves

PC(Polycarbonate)

PC is very tough with temperature resistance and dimensional stability, can be made transparent but in high cost.

Common applications:Automotive (panels, lenses, consoles), bottles, containers, housings, light covers, reflectors, safety helmets and shields

PC+ Glass-Filled

Glass-filled Polycarbonate is a strong and tough material ideal for many industrial applications.

Common applications: Pulleys, medical devices

PMMA(Acrylic)

PMMA is a transparent polymer with good tensile, scratch resistant, can be transparent and optical clarity in low/medium cost

Common applications:display stands, knobs, lenses, light housings, panels, reflectors, signs, shelves, trays

PP(Polypropylene)

PP is in lightweight with heat resistance, high chemical resistance, scratch resistance and natural waxy appearance that is tough and stiff in low cost.

Common applications: Automotive (bumpers, covers, trim), bottles, caps, crates, handles, housings

PP++ Glass-Filled

Glass Filled PP Compound is manufactured by compounding Polypropylene Homo-Polymer with fine grade of Glass, with suitable grade of processing Aid, Heat stabilizer and Anti-oxidant.

Common applications: housings handles, enclosures

PE(Polyethylene)

PE has a low melting point, high ductility, high impact strength, and low friction.

Common applications: Films, bags, electronic insulation, toys.

LDPE(Polyethylene - Low Density)

LDPE is a soft, flexible, tough, and lightweight plastic with good corrosion resistance in natural waxy appearance and low cost

Common applications: Containers, bags, tubing, kitchenware, housings, covers

HDPE(Polyethylene - High Density)

HDPE is tough and stiff with excellent chemical resistance, high tensile strength, high impact resistance and a high melting point.

Common applications: Chair seats, housings, covers, containers and caps

Nylon - Glass Filled & 6/6

Nylon 6/6 has high mechanical strength and rigidity with fatigue resistance, chemical resistance in low creep and low friction with medium/high cost

Common applications: handles, levers, small housings, zip ties&gears, bushings

Nylon - Glass Filled is much stiffer and has better tensile strength than standard Nylon. It also has a low coefficient of friction and high thermal resistance.

Common applications: Bearings, washers, a lightweight substitute for metals where appropriate

ASA(Acrylonitrile Styrene Acrylate)

ASA is an ABS alternative with improved weather resistance.

Common applications: Automotive parts Enclosures, large panels

HIPS(High Impact Polystyrene)

HIPS is easy to mold, recycle, and has high impact strength and stiffness.

Common applications: Packing, dishware, displays

GPPS(Polystyrene - General purpose)

GPPS is brittle, transparent but in low cost.

Common applications: Cosmetics packaging, pens

PBT(Polybutylene Terephthalate)

PBT is similar to PET plastic and a member of the polyester family. PBT is better suited to lower molding and use temperatures. It has high heat and chemical resistance.

Common applications: Automotive (filters, handles, pumps), bearings, cams, electrical components (connectors, sensors), gears, housings, rollers, switches

PBT+Glass Filled

Glass-filled PBT is much stiffer and has greater tensile strength than standard PBT. It also has high heat and chemical resistance.

Common applications: automotive applications, Fire-retardant applications

PET(Polyethylene terephthalate)

PET is the most common material for plastic bottles of water and other drinks. It is also commonly known as polyester and is used to make synthetic fibers.

Common applications: Plastic water bottles, packaging

PC/ABS

PC/ABS is a blend of polycarbonate and ABS that is to get the best properties of both base materials—heat resistance and flexibility. This blend is also more easily processed during injection molding than either of the base materials.

Common applications: Enclosures, large panels;

PVC(Polyvinyl Chloride)

PVC has high hardness, mechanical and electrical insulation properties. It is chemically resistant to many liquids.

Common applications: Medical containers, construction components, piping, cables

PEI(ULTEM)

PEI is a amber color plastic with high temperature resistance and very high dielectric strength, making it great for medical instrument components and electrical insulation parts.

Common applications: Electrical components (connectors, boards, switches), covers, Medical instrument components

PEEK(Polyetheretherketone)

PEEK has high temperature, chemical, and radiation resistance with low moisture absorption.

Common applications:Aircraft components, electrical connectors, pump impellers, seals

PPS(Polyphenylene Sulfide)

PPS has a very high strength and heat resistance with good flow and dimensional stability.

Common applications: fuel system components, guides, switches, electrical insulation, membranes, packaging

PPO(Polyphenylene Oxide)

PPO has great dimensional stability and good electrical properties with low water absorption and high cost

Common applications: Automotive (housings, panels), electrical components, housings, plumbing components

PPA(Polyphthalamide)

PPA is comparable to nylon with higher stiffness, strength, and thermal properties. It has good creep resistance and dimensional stability.

Common applications: Automotive, oil and gas, plumbing components

SAN (Styrene Acrylonitrile)

SAN(AS ) is the Polystyrene alternative with higher thermal and chemical resistance and is hydrolytically stable.

Common applications: Housewares, knobs, syringes

TPE(Thermoplastic Elastomer)

TPE has the look and feel of a rubber-like material but is a thermoplastic that can be re-melted. TPE has good thermal properties and stability at a wide range of temperatures that can be made in different hardness.

Common applications: Automotive applications, household appliances

TPU(Thermoplastic polyurethane)

TPU is is an elastic material with good resistance to oil, grease, and abrasion.

Common applications: Medical device applications, mobile electronic devices

TPV(Thermoplastic Vulcanizates)

TPV is part of the TPE material family. It has the closest in properties to EPDM rubber and has high-temperature resistance and excellent elastisity.

Common applications: Automotive applications, household appliances, sealing applications

PS:We can also source custom materials upon request to meet your product exact application

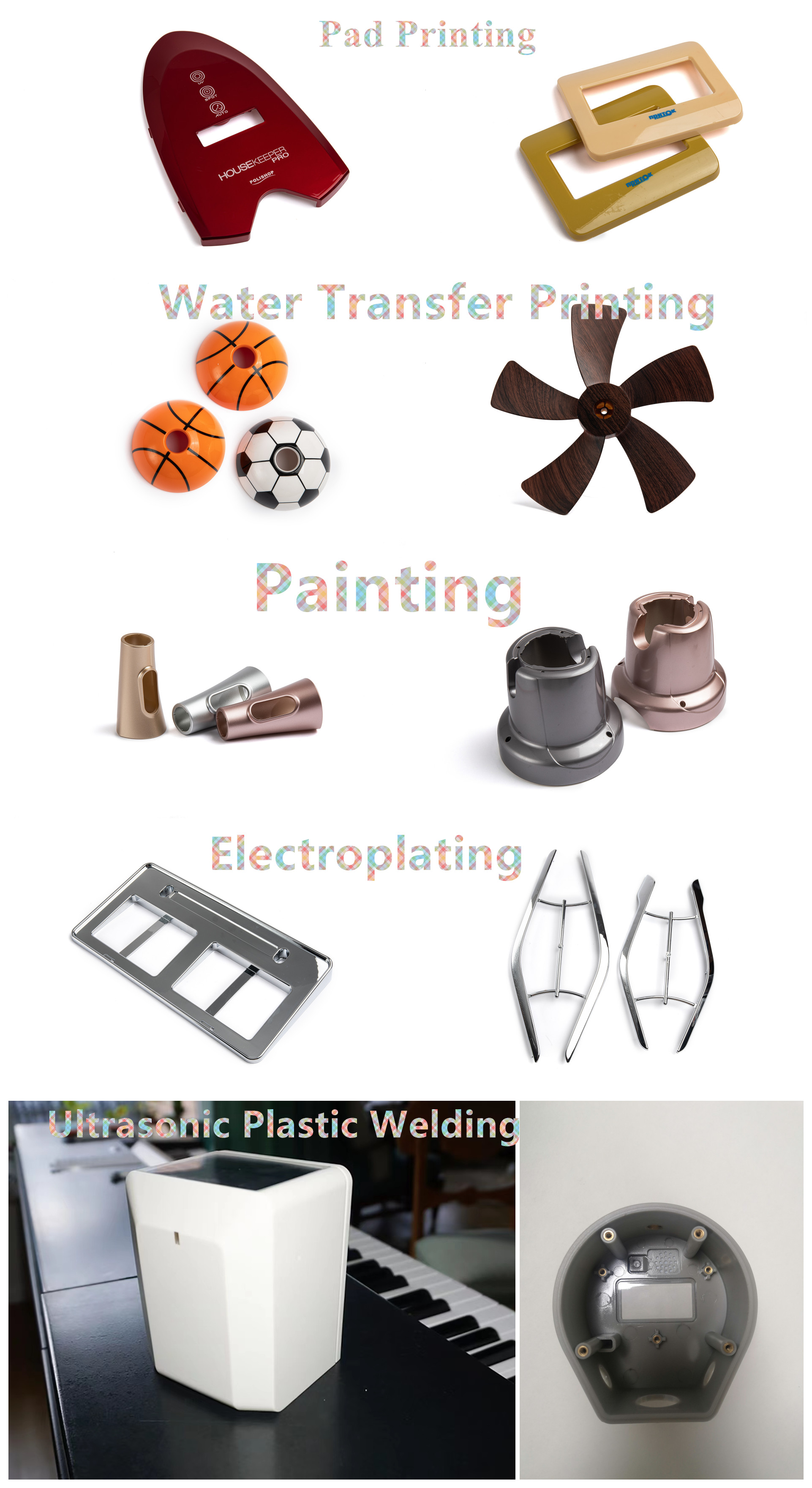

Secondary Operations After Injection

Pad Printing

Pad printing is a printing process that can transfer a 2D image/logo/text onto a 3D surface.

Water Transfer Printing

It is also known as immersion printing, water transfer imaging, hydro dipping, which is a method of applying printed designs to 3D surfaces.

Painting

Glossy and matte various color painting are both available to be applied on.

Electroplating

It is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current.

Ultrasonic Plastic Welding

It is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld.

Injection Molding Solutions

Rapid Injection Molds:

Ideal for part design validation, request prototype or small volume production.

√ Quick lead time

√ No MOQ request

√ Complex design accepted

Mass Production Injection Mold

Ideal for bigger volume production parts, tooling cost are higher than rapid injection molds but result in a lower part unit price.

√ Up to 500,000 cycles of mold shot life

√ Production grade steel tooling&multi-cavity tooling

√ Can be used for automatic injection process

Injection Molding Case Study