Choosing the right injection molding specialist is critical to the success of your project. The following are some of the key factors to consider when selecting an injection molding specialist:

1.Experience: Look for injection molding specialists who have experience working with the specific materials and processes involved in your project. Experienced specialists are more likely to anticipate and solve potential problems, resulting in a higher quality end product.

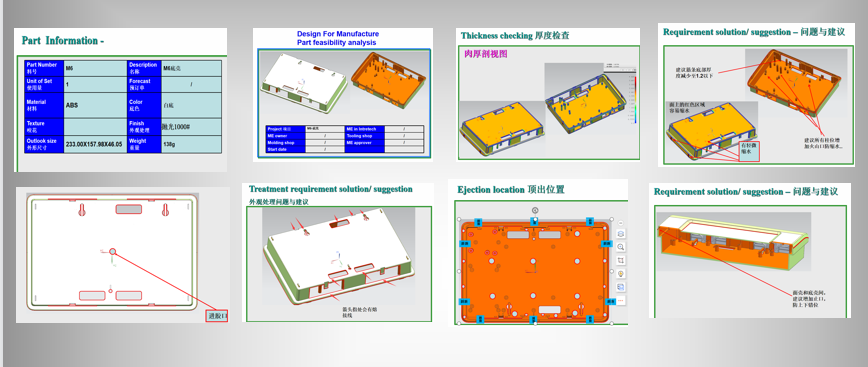

2. Technical Expertise: Consider the expert's technical expertise in injection molding. Look for professionals who have a deep understanding of the injection molding process and can provide guidance on best practices for your specific project.

3.Reputation: Check the reputation of the expert by reading reviews and testimonials from previous clients. A good reputation is a strong indicator of the quality of a professional's work, reliability and customer service.

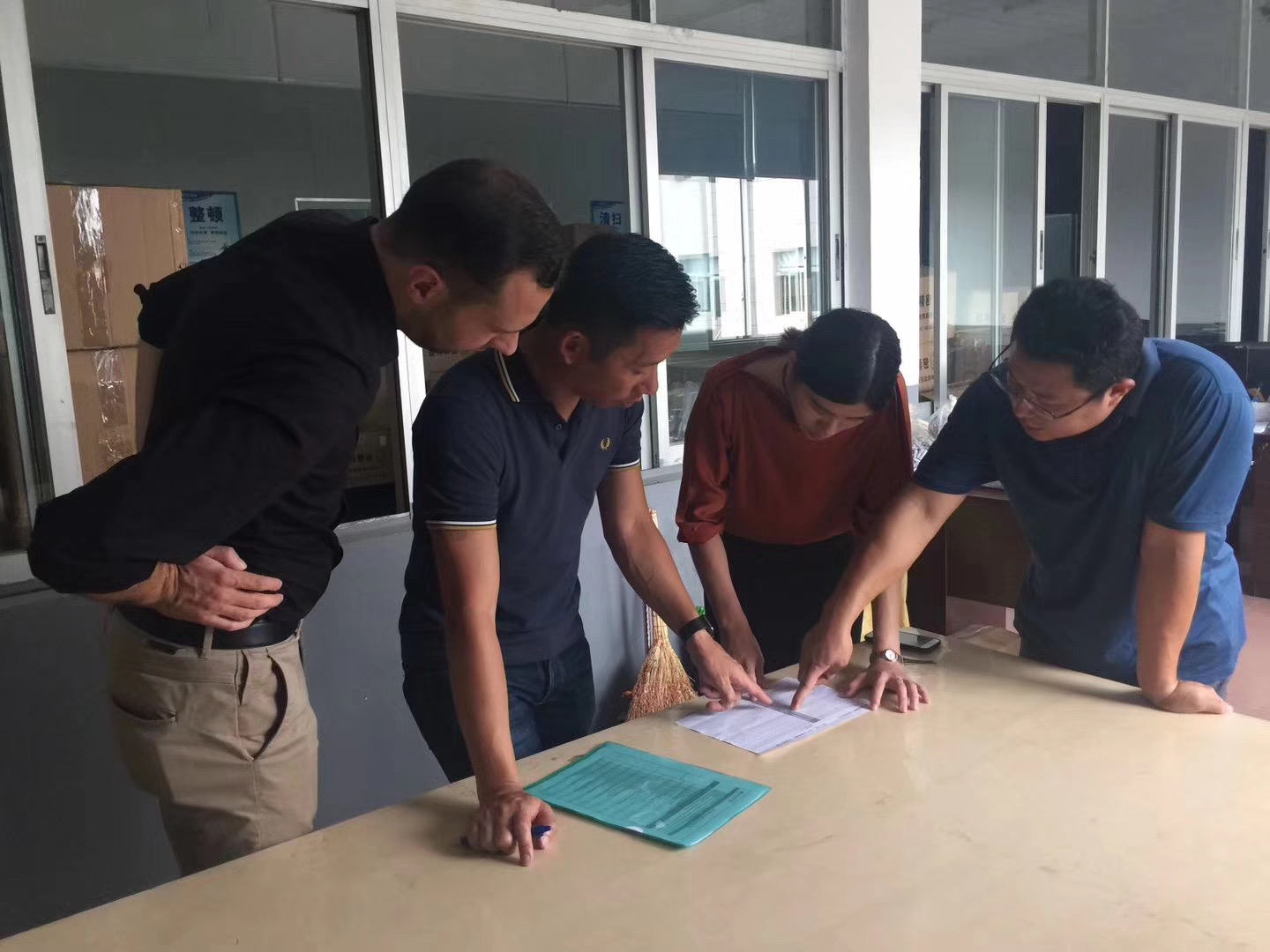

4.Communication: Choose an injection molding specialist who can communicate clearly and effectively. The specialist should be able to explain complex concepts in an easy-to-understand manner and be responsive to your questions and concerns.

5. Location: Consider the location of the injection molding specialist. A professional closer to your facility may be able to provide more personalized attention and faster response times.

6.Cost: Compare the costs of different injection molding specialists. While cost should not be the only factor you consider, it is important to find a specialist who can provide quality work within your budget.

7.Technical competence: Assess the technical competence of the specialist or the company they work for. Check if they have access to the latest technology and equipment, and their ability to handle complex projects.

8.Quality Control: Check the quality control processes of the specialists to ensure that they deliver a high quality end product. Look for professionals who have a comprehensive quality control program in place to ensure that each part meets your specifications and requirements.

9. Turnaround time: Consider the turnaround time of the specialist, or the time it takes to produce the part. Look for professionals who can meet your project deadlines and who have a track record of delivering projects on time.

10. Customer Service: Choose an injection molding specialist who can provide excellent customer service. This specialist should be responsive to your needs and concerns and be able to provide ongoing support throughout the project.

By considering these factors, you can find an injection molding specialist who can provide the expertise and guidance to ensure the success of your project.

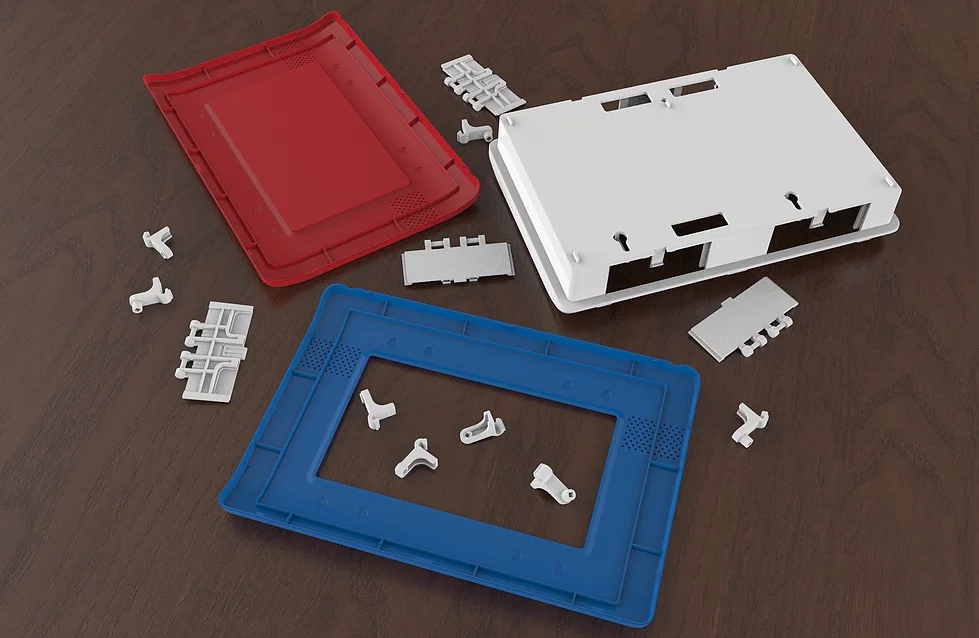

Of course,you can trust us ,Xiamen Ruicheng .With advanced manufacturing technology and a highly skilled team,Xiamen Ruicheng has always maintained an excellent competitive advantage. We custom our manufacturing services to meet your specific product design needs.

Our business model is based upon providing a cost-effective solution that benefits customers at all stages of their product development. Our greatest asset is our customer base, which has grown rapidly through customer’s word-of-mouth around the world; amongst them, it covers from independent inventors or designers to large-scale industrial, commercial, medical, automotive and even aerospace companies.

If you’re newly in need of a manufacturing company for your design or tired of all the hoopla that your current suppliers are giving you, please contact us for a quote or manufacturing consultation today.

Post time: Jun-13-2023