The purpose of quality control is not only to prevent defects, but also to ensure that parts are manufactured according to design specifications and operate properly.

A good quality control program helps keep production on time and on budget, and also helps avoid product safety issues.In the custom fabrication of metal parts, it is crucial to ensure that their quality meets the requirements. Quality control is a key task that involves multiple aspects of dimensional measurement and quality management. In this blog, Xiamen Ruicheng, a supplier of customized metal parts, will discuss how we ensure that the quality of our metal parts meets our customers' requirements.

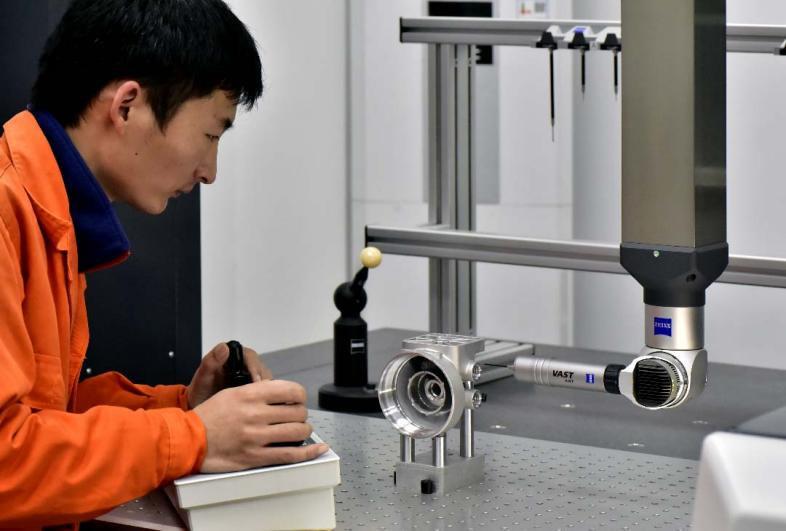

1.Advanced Dimensional Measurement Technology:

Xiamen Ruicheng utilizes advanced dimensional measurement technology, including Coordinate Measuring Machines (CMM), optical measuring instruments and precision measuring tools. These advanced tools and equipment are able to accurately measure the dimensional parameters of metal parts to ensure that they are consistent with design requirements. Through precision measurement, they are able to detect and correct any dimensional deviations in a timely manner, thus ensuring that the product's geometry conforms to standards.

By utilizing Coordinate Measuring Machines (CMMs), Xiamen Ruicheng is able to capture precise data points in three-dimensional space, allowing for comprehensive measurements of complex metal parts. In addition to CMMs and optical instruments, Ruicheng uses a variety of precision measuring tools, including calipers, micrometers and gauges. These tools are capable of accurately measuring a wide range of dimensions such as length, diameter, angle, etc., ensuring that every critical parameter of a metal part is within specified tolerances.

2.Quality Management System:

Xiamen Ruicheng has established a perfect quality management system to ensure that the quality of metal parts meets the requirements. They adhere to the ISO 9001 quality management system standards and strictly implement quality control processes and procedures. This system covers the entire process from purchasing raw materials to manufacturing to final shipment, ensuring that each step is strictly controlled and monitored.

Firstly, at the raw material procurement stage, we ensure that the metal materials purchased meet the quality requirements. In the manufacturing process, Xiamen Ruicheng strictly implement the standardized process flow and operating instructions. Each process has detailed records and operational requirements, and strict self-inspection and mutual inspection. Key processes and key control points for key monitoring and sampling tests to ensure that the quality of the product meets the requirements.

3.Continuous Improvement and Customer Collaboration:

In addition to internal improvement measures, Xiamen Ruicheng also attaches great importance to cooperation with customers. We maintain close communication and cooperation with our customers to understand their needs, requirements and feedback. Through active interaction with our customers, we are able to accurately grasp their expectations and incorporate this feedback into quality improvement programs.

In cooperation with customers, Xiamen Ruicheng focuses on establishing long-term stable partnerships. We conduct regular meetings and communication with customers to jointly discuss and solve problems and seek common opportunities for improvement. By building a partnership of trust and mutual confidence, we are able to better understand our customers' needs and provide them with metal parts products that better meet their expectations.

Xiamen Ruicheng has demonstrated exceptional practice and commitment to quality control of metal parts. Through advanced dimensional measurement techniques, material analysis and quality management systems, we ensure that the quality of our metal parts meets requirements and satisfies customer needs. Continuous improvement and close cooperation with customers are the key factors in maintaining excellence in quality control at Xiamen Ruicheng. Our efforts and commitment make us a reliable partner in providing quality customized metal parts to our customers. If you have related customized metal parts needs, please feel free to contact us!

Post time: Feb-22-2024