3D Printing technologies have been around since the ‘80s, recent advances in machinery, materials and software have been made them accessible to a wider ranger of businesses beyond a few high-tech industries. Today,desktop and bench top 3D printers accelerate innovation and growth across various industries, including engineering, manufacturing,dentistry, healthcare and more. So if you want to know more information about 3D printing, please read this article and continued follow our website.

What is 3D Printing

3D printing, also aptly called additive manufacturing, creates three-dimensional parts by building up material, layer by layer, based on digital models created using computer-aided design or CAD.

How 3D printers work

1.Digital 3D models are either designed using CAD software or developed from a 3D scan.

2.The design is imported into a print preparation software to specify print settings and slice the digital model into layers that represent horizontal cross-sections of the part.

3.Sent these instructions to the printer.

4.Depending on the technology and the material,the printed parts generally require some sort of post-processing,such as washing, depowdering, removing support structures,post-curing or sanding.

FDM

FDM is the most widely used form of 3D printing at the consumer level,fueled by the emergence of affordable machines for hobbyists.FDM 3D printers build parts by melting an extruding thermoplastic filament,which a printer nozzle deposits layer by layer.FDM printers work with a range of standard thermoplastics,such as abs,PLA and various blends.the technique is well suited for basic proof-of-concept models,as well as quick and low-cost prototyping of simple parts.

SLA

SLA was the world’s first 3D printing technology,and it remains one of the most popular technologies for professionals.SLA resin 3D printers work by using a laser to cure liquid resin into hardened plastic and a process called photopolymerization.Because SLA parts have the highest resolution and accuracy,the clearest details,and the smoothest surface finish of all plastic 3D printing technologies,resin 3D printing is a great option for producing highly detailed prototypes and parts requiring tight tolerances and smooth surfaces,such as molds and functional parts.SLA 3D printing also offers the widest range of materials for various applications.

SLS

SLS is the most common additive manufacturing technology for industrial applications.SLS 3D printers use a high-powered laser to fuse small particles of polymer power.The unfused powder supports the part during printing,eliminating the need for support structures.This makes SLS ideal for complex geometries,including interior features,undercuts,thin walls and negative features.The most common material for selective laser sintering is nylon.

Benefits of 3D Printing

1.Speed

With traditional manufacturing processes, it can take weeks or months to receive a part. 3D printing turns CAD models into physical parts within a few hours, producing parts and assemblies from one-off concept models to functional prototypes and even small production runs for testing. This allows designers and engineers to develop ideas faster, and helps companies to bring products more quickly to the market.

2.Cost

With 3D printing, there’s no need for the costly tooling and setup associated with injection molding or machining; the same equipment can be used from prototyping to production to create parts with different geometries. As 3D printing becomes increasingly capable of producing functional end-use parts, it can complement or replace traditional manufacturing methods for a growing range of applications in low- to mid-volumes.

3.Customization

From shoes to clothes and bicycles, we’re surrounded by products made in limited, uniform sizes as businesses strive to standardize products to make them economical to manufacture. With 3D printing, only the digital design needs to be changed to tailor each product to the customer without additional tooling costs. This transformation first started to gain a foothold in industries where custom fit is essential, such medicine and dentistry, but as 3D printing becomes more affordable, it’s increasingly being used to mass customize consumer products.

4.Design Freedom

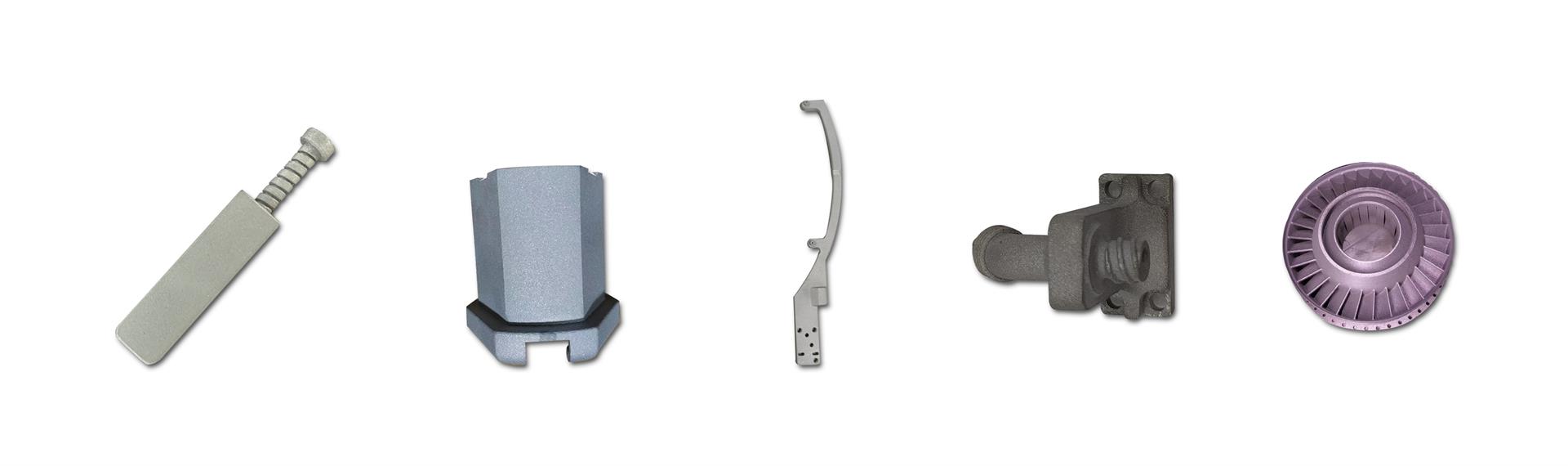

3D printing can create complex shapes and parts, such as overhangs and organic shapes, that would be costly or even impossible to produce with traditional manufacturing methods. This provides the opportunity to consolidate assemblies into less individual parts to reduce weight, alleviate weak joints, and cut down on assembly time, unleashing new possibilities for design and engineering.

3D Printing applications

Healthcare

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices customized to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room. Especially in area of dentistry, digital dentistry reduces the risks and uncertainties introduced by human factors, providing higher consistency, accuracy, and precision at every stage of the workflow to improve patient care. 3D printers can produce a range of high-quality custom products and appliances at low unit costs with superior fit and repeatable results.

Rapid prototype

Rapid prototype is so common that is practically become a synonym for it. Rapid prototyping with in-house 3D printers empowers engineers and product designers to create realistic and functional prototypes within a day and carry out multiple iterations of design, size, shape or assembly based on results of real-life testing and analysis, helping them guide products through a series of test stages.

Models and props

3D Printing is a great tool for creating complex and models with a smooth surface, at the same time it can saving time and money. at now High definition physical models are widely used in area of sculpting, character, modeling, dental, and prop making. such as medical models, movie props, educational tools, architecture models, and more. Following the technology develop, 3D Printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies.

3D Printing is not a futuristic concept anymore. There are more 3D printers in use today than ever before. And they may being used to shape your field.

If you have any requirement please contact us! We will try our best to help you to solve the problem.

Post time: Mar-21-2024