Rubber molding is a manufacturing process that involves shaping rubber materials into specific forms and dimensions. This process is commonly used to produce a wide range of rubber products, including seals, gaskets, O-rings, and various industrial components.

There are several methods of rubber molding, including compression molding, transfer molding, injection molding, and liquid injection molding. Each method has its own advantages and is suitable for different types of rubber products.

Rubber molding is a versatile process that allows for the production of complex shapes and intricate designs. It is widely used in industries such as automotive, aerospace, electronics, and medical devices.

Overall, rubber molding plays a crucial role in the manufacturing of various rubber products, providing a cost-effective and efficient method for producing high-quality components.

Today we will pay attention to show you about rubber molding technology from technology type, rubber molding advantages and applications.

WHAT IS RUBBER MOLDING?

Rubber molding is a manufacturing process used to convert uncured rubber into a usable product. This is accomplished through a variety of processes, including heating and reshaping the rubber in a metal cavity. The three main types of molding are injection molding, compression molding, and transfer molding.

Three type of rubber molding technology

Rubber injection molding is accomplished by injecting uncured rubber into a mold. The rubber remains in the mold for a certain period of time until it vulcanizes into its final shape. Although injection molding is a type of rubber molding, it can also be used on many different materials, such as metal and glass.

Rubber Compression Molding

Rubber compression molding is accomplished by placing a preformed shape of uncured rubber into the cavity of a heated mold and then using hydraulic pressure to seal it. The rubber is kept in a heated cavity until it is molded into its final shape.

Rubber Transfer Molding

Rubber transfer molding is accomplished by loading a certain amount of uncured rubber into a transfer tank. The punch is then closed and the preform is pushed into the part cavity through the runner and gate system. The rubber is held in a heated cavity for a specific amount of time to cure it into its final shape.

The Magic of Rubber Molding

Rubber molding is a versatile and efficient process that allows you to easily replicate intricate details and create complex shapes. Whether you're a product designer, artist, or engineer, understanding the nuances of rubber molding can give your projects a major boost.

Precise copy

One of the outstanding features of rubber molding is its ability to reproduce the tiniest details. This kind of exact reproduction is invaluable in industries where complex designs are critical. Examples include jewelry making, miniature figurine making, or restorative dentistry.

Material flexibility

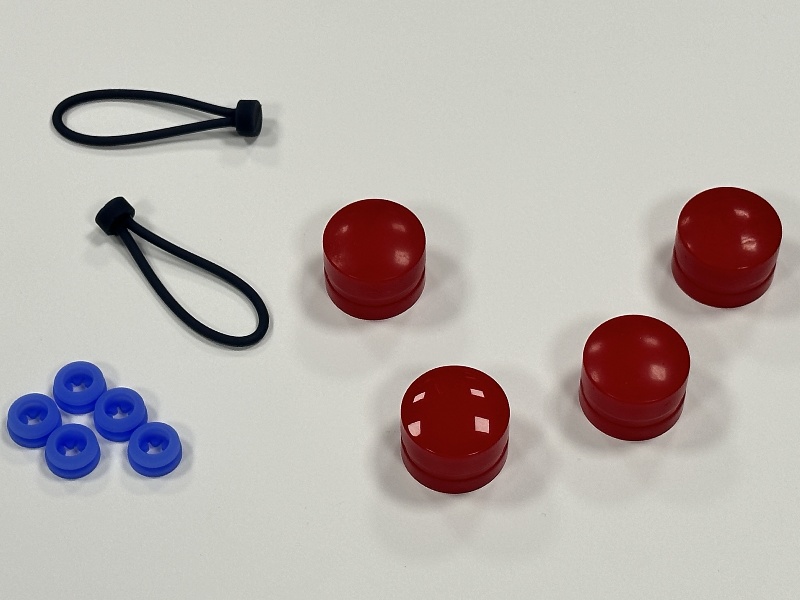

Rubber molds can be made from a variety of materials, including resin, plastic, and even food-grade materials like sealing caps. This versatility opens up a world of possibilities for experimentation and innovation in various fields.

Cost-effectiveness

Advanced rubber molding technology provides cost-effective solutions for small-scale and large-scale production. The ability to make precise molds reduces material waste, saving you money in the long run.

Save time

The speed of rubber molding processes, such as injection molding, can significantly reduce production times. This means your projects turn around faster and you can meet tight deadlines.

Design freedom

Rubber molding technology gives you the freedom to experiment with complex designs that may be difficult to achieve through other methods. This creative flexibility allows you to push the boundaries of your projects.

Rubber molding is a versatile process that finds application in various industries. Some common applications of rubber molding include:

1. Automotive industry: Rubber molding is used to produce a wide range of automotive components such as seals, gaskets, O-rings, hoses, and vibration dampeners.

2. Medical industry: Rubber molding is used to produce medical devices, such as seals, gaskets, and custom rubber components for medical equipment.

3. Electronics industry: Rubber molding is used to produce protective covers, grommets, and seals for electronic devices and components.

4. Consumer goods industry: Rubber molding is used to manufacture a variety of consumer products, including rubber grips, seals, and gaskets for household appliances and tools.

5. Sporting goods industry: Rubber molding is used to produce components for sporting goods, such as grips, seals, and protective padding for equipment.

6. Toys: Action figures,Rubber molding enables the production of flexible and durable rubber action figures and characters.

These are just a few examples of the many applications of rubber molding across different industries. The process is valued for its ability to produce custom-designed rubber components with high precision and durability.

Summary

This article analyzes the characteristics of rubber molding, , as well as the molding methods, which will hopefully help your rubber material project.

The article mentions Rubber Molding technology type and it's advantages, which require high experience of injection mold suppliers and injection molding product suppliers.

If you have a project involving these two processes, it is recommended to confirm that the injection mold factory and injection molding product factory have experience in making similar products to ensure the smooth implementation of the project or you can contact us, our professional teams will answers your questions.

Post time: May-13-2024