Injection molding is a popular manufacturing process that produces a wide range of plastic products. The color of the plastic material is a critical factor that determines the quality and aesthetic appeal of the final product. In this article, we will discuss how injection molding colors are controlled, with a focus on our factory's strict quality control process.

Material Selection

The first step in controlling the color of injection molded parts is material selection. Xiamen Ruicheng carefully chooses raw materials based on their properties and color consistency. We select materials from reputable suppliers who provide consistent quality and color. We also take into account the environment in which the product will be used and the required level of UV resistance.

Color Masterbatch

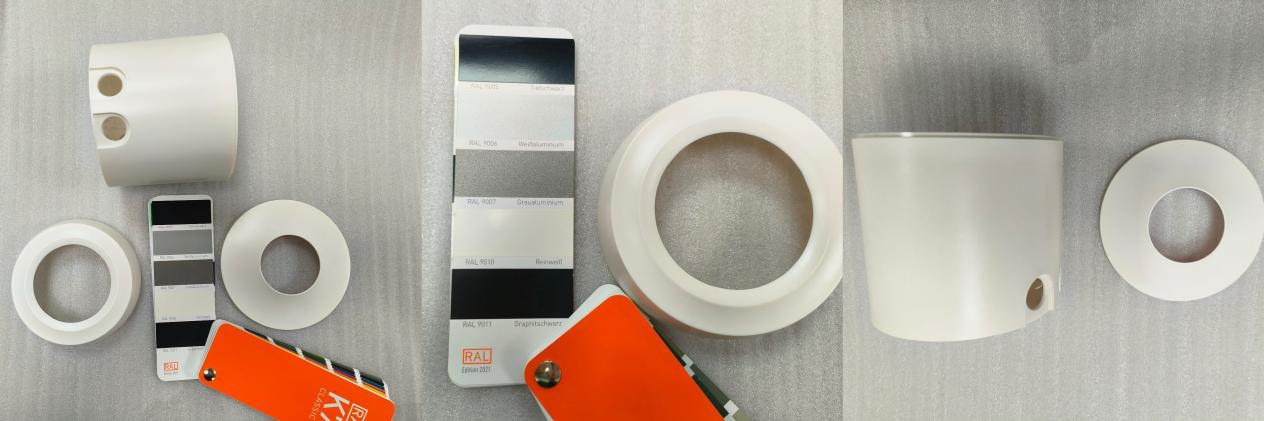

Color masterbatch is a concentrated mixture of pigments and additives that are added to the raw plastic material to achieve the desired color. Xiamen Ruicheng uses high-quality color masterbatch from trusted suppliers to ensure consistent color and quality.

Color Control During Processing

Color control during processing is critical in ensuring that the final product meets the required color specifications. Xiamen Ruicheng uses advanced injection molding machines with precise temperature and pressure controls to ensure that the plastic material is processed under optimal conditions. We also monitor the cooling rate, mold temperature, and melt flow rate to ensure consistent color throughout the manufacturing process.

Color Measurement and Analysis

Xiamen Ruicheng has a strict color measurement and analysis process to ensure that the final product meets the required color specifications. We use a colorimeter or spectrophotometer to measure the color of the parts and compare them to a standard reference. If the color is not within the required range, we adjust the processing parameters or color masterbatch to achieve the desired color.

Quality Control

Xiamen Ruicheng has a rigorous quality control process that includes color inspection. We inspect each part for color consistency, and any part that does not meet our color standards is rejected. We also perform regular color checks throughout the manufacturing process to ensure color consistency and quality.

In conclusion, controlling the color of injection molded parts is critical in producing high-quality plastic products. Xiamen Ruicheng has a strict control process that ensures consistent color and quality in our products. We carefully select raw materials, use high-quality color masterbatch, control processing parameters, measure and analyze color, and implement strict quality control processes to ensure that our products meet the highest standards.

More questions on the colors controls ,please contact us ,we provide the free consult and professional solutions here

Post time: Jun-15-2023