What is TPU

TPU is a stands for Thermoplastic Polyurethane. It is a subset of TPE and is a soft polyether type polyurethane that comes in a range of hardness grades. At the same time, TPU also as the one of material be commonly used in injection industry. But today we want to show you another craft to process TPU, that is 3D Printing. Have you ever thought about 3D printing flexible parts? If so TPU is definitely a material to add your list.

Typical properties

There are many properties of TPU. Such as:

• High elongation and tensile strength

• Excellent abrasion resistance

• Low-temperature performance

• Excellent mechanical properties, combined with a rubber-like elasticity

• High transparency

• Good oil and grease resistance

How are TPU parts made?

For TPU product, manufacturer often use injection craft to make it. We should admit that is a cost-effective way of producing parts in mass quantities but has limitations in terms of geometric flexibility or customization. Injection molded parts are standardized in order to be produced in quantities of hundreds of thousands to millions — so for industries like medical device manufacturing or sporting goods or other industry, there is a demand for craft that lend themselves better to low volume production or customization.

Why choose TPU to 3D Printing

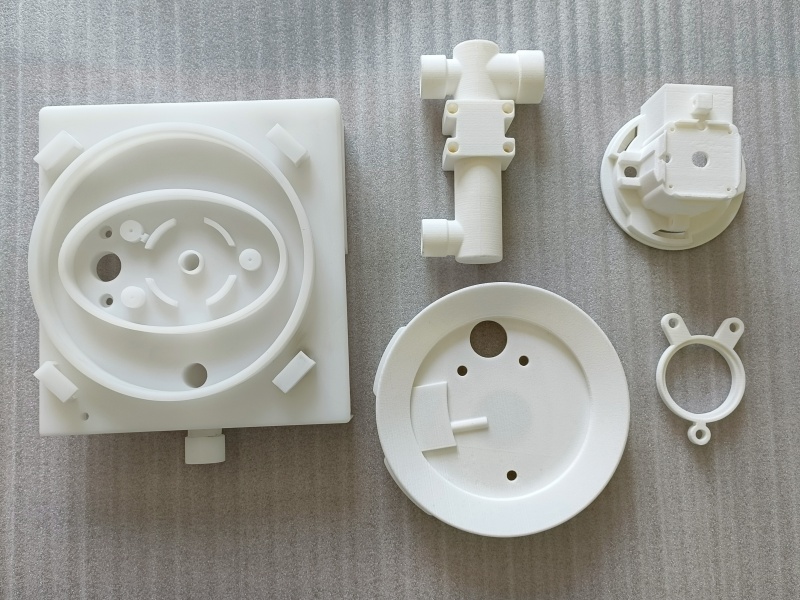

3D printing TPU materials presents possibilities for those parts need geometric complexity, personalized design and need more cost-effective low-volume production.

At now there are various options for TPU 3D printing, including FDM and SLS technologies. As 3D printing technology and materials have advanced, the number of manufacturers incorporating this technology into their workflow will grown exponentially.

3D printing TPU can also help manufacturers meet the customer's demand for customized and personalized goods. According to a study, in some categories, more than 50% of consumers expressed interest in purchasing customized products or services, with the majority of them willing to pay more for a customized product or service. For applications in which TPU and rubber are commonly used, such as protective devices like helmets or insoles, 3D printed TPU parts are perfect for mass-customized helmet paddings, sports equipment, goggles, headsets, or ergonomic gripping components for tech products.

Applications of TPU 3D Printing

3D printing with TPU enables businesses to bring prototyping capacity under their own roof, cutting down lead times.

For instance when Prototyping a sports helmet,in order to meet requires hard shell as well as the soft cushioning inside. Our companies are working to design a new technology and use TPU to solve this problem. Those new cushions will be made with lattice structures and impact negation technology. At the same time, our 3D Printing technology gives you access to multiple materials covering a wide range of needs, allows you to keep development and manufacturing all in-house, and manage the design of many different types of components with one technology.

Offering exceptional durability and toughness, 3D printed TPU is ideal for prosthetics, orthotics, patient-specific appliances, and medical devices.

we can 3D printing the flexible and strong parts creates new opportunities for medical professionals by combining the high tear strength and elongation-at-break of TPU materials with the design freedom and durability of SLS 3D printing.

TPU is a flexible elastomer, making it ideal for 3D printing medical parts such as:

• Medical device prototypes and end-use medical devices and components

• Orthotic pads and prosthetic liners

• Wearables, seals, bumpers, and tubes

• Splints, cranial remolding helmet

• Athletic and corrective insoles

Things to note when using TPU 3D printing

Temperature

When printing with TPU, it's crucial to adjust the print settings accordingly. This process involves setting the correct temperature for the nozzle and the heated bed, adjusting the print speed, and configuring retraction settings.

Most slicers will have a preset profile for materials like TPU and TPE. Only adjust the settings if you think the presets are giving inadequate results.

The temperature of the nozzle and the heated bed plays a crucial role in ensuring the TPU filament melts and bonds correctly. Generally, the recommended nozzle temperature for TPU is about 230 °C. However, the exact temperature depends on the specific brand and type of TPU material being used.

The temperature of the heated bed also requires adjustment when printing with TPU material. A heated bed helps to improve the adhesion of the TPU filament to the print surface and reduce warping. The recommended bed temperature for TPU printing typically ranges between 40 and 60 °C.

Speed

Print speed is another important setting to adjust when printing TPU parts.

Due to the flexibility of TPU, it's generally advised to print at slower speeds than you would with more rigid materials like PLA or ABS. A print speed between 15 to 20 millimeters per second is often recommended for TPU. Slower print speeds allow for better control over the filament and help to prevent issues such as stringing or oozing.

Start cooperating with Ruicheng on TPU 3D printing

Accounting to our 3D printing power opens up possibilities for customer to improve their design process. And through high-quality iterative prototyping, you can customize the parts you need based on the end use.

Our 3D printing machine is compact, affordable, and accessible, that enables new applications. Our team can give you more control and flexibility in your design and manufacturing process, no matter which application or industry you’re a part of.

To learn more about 3D printed TPU parts of RuiCheng, you can contact our sales team to discuss your unique application.

Post time: Apr-08-2024