Overview

Part's safety and accuracy are critical to the medical industry.As a professional Medical device manufacture, RuiCheng can provide durable and medical-grade plastic injection molding parts, at the same time our parts can satisfy product specifications and end-user needs. This article will introduce device parts about medical to you.

Application

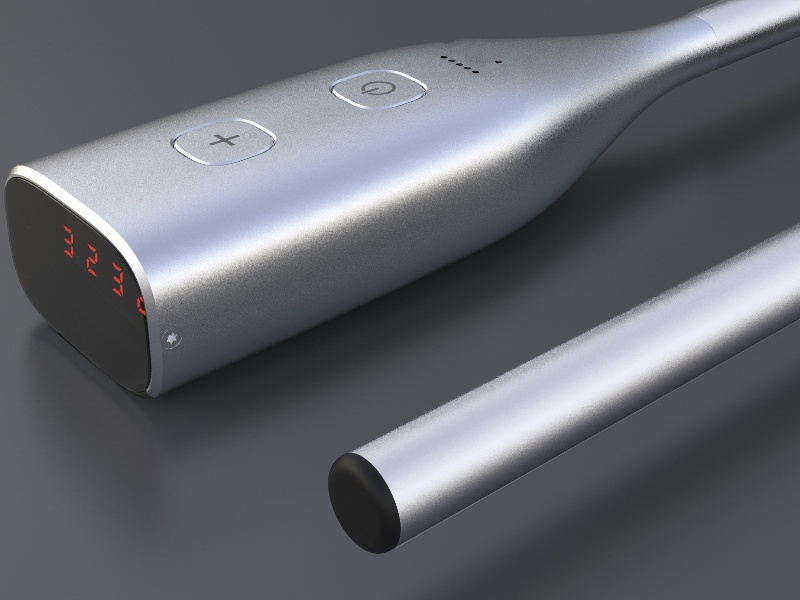

At now, many medical devices all made by injection or cnc technology. Some common medical devices are listed below:

X-ray shell

MRI machines

Catheters

Prostheses

test tube

These devices and associated subcomponents can be machined using various materials, including injection, aluminum, titanium, PE, PVC, and ABS.

Craft

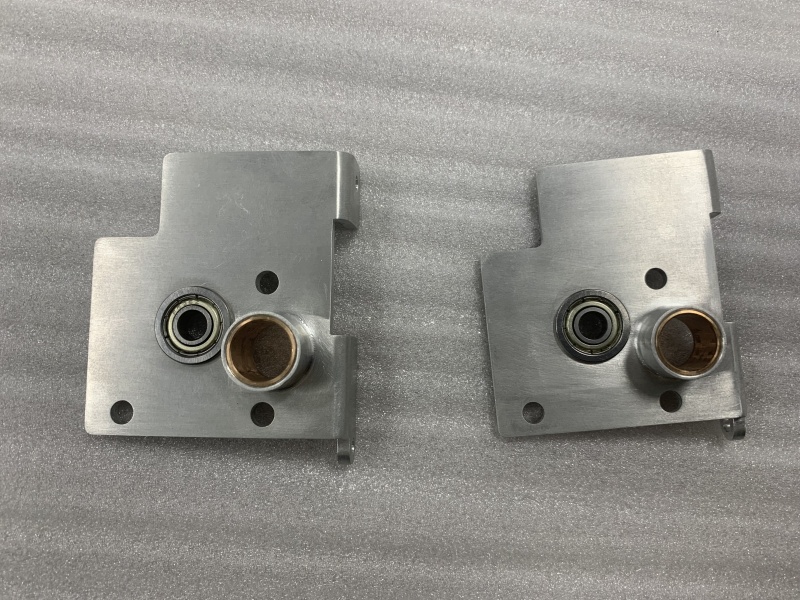

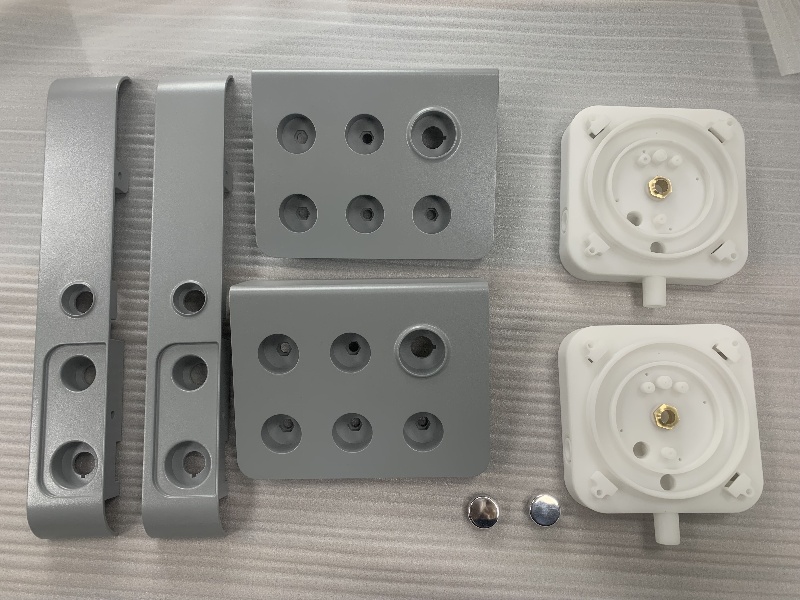

CNC

Recent years, CNC technology use to be apply in medical industry in wildly, manufacturer can rely on design to create CNC mold and make to product finally. While plastic medical parts can be create by molded, cast, or extruded, CNC as the first step of process, it is often used to produce the molds or extrusion dies required for the production processes.

INJECTION

Advancements in material manufacturing techniques and technologies have led to the widespread use of plastics in modern manufacturing operations. In the medical and pharmaceutical industries, plastics are often used alongside the injection molding process to produce prototypes and full-production units of medical device and equipment components. As newer plastic materials and component designs are developed, injection molded plastics have increasingly contributed to lower infectious disease rates, better pain management, and lower medical costs.

Material

1.plastic

The injection molding process accommodates a wide range of plastic materials, making it well-suited to produce medical and pharmaceutical parts from whatever medical-grade plastic is required for the project. There are numerous plastics suitable for medical injection molding operations, each of which offers unique properties and performance characteristics. Common plastic material options for medical injection molding include:Polyethylene, Polypropylene, Polystyrene, Polycarbonate.

2.Metal

Any material considered acceptable for medical devices must meet high standards of reliability and performance. Below are some common materials used for medical CNC machining:

•Aluminum

Aluminum is often used in the medical industry due to its lightweight, high strength-to-weight ratio, durability, and corrosion resistance. It is also biocompatible and can be used for limited internal use in the human body.

•Stainless Steel

Stainless steel’s desirable properties including strength, toughness, corrosion resistance, impact resistance, and biocompatibility make it ideal for many uses in the medical industry. Its thermal stability and outermost passivation layer allow parts to be easily cleaned and sanitized.

•Titanium and Titanium Alloys

Titanium and its alloys are used in the medical industry because of their strength, low weight and density, and corrosion resistance. Titanium is one of few inert metals and unaffected by bodily fluids and tissue.

•Brass Polyethylene (PE)

Polyethylene (PE) is commonly used in the medical field due to its ability to retain structural integrity even after several sanitation cycles and biological inertness. Xometry can both directly machine PE to a finished product and various plastic manufacturing tooling needed to fabricate parts.

•Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) is an ideal material for use in the medical industry. Some of its desirable properties include flame resistance, chemical resistance, and durability.

Want to Learn More?

To see the product of our work in the medical industry, check out this case study documenting how we made the mold design for a ABS TEST TUB.

Contact us! You’ll also learn about how our custom capabilities.

Post time: Mar-28-2024