Engraving, like sculpture, has a long and fascinating history that spans various cultures and time periods. Engraving is the practice of incising a design onto a hard, flat surface, often for the purpose of creating prints or reproductions. The history of engraving can be traced back to ancient civilizations, where it was used for decorative, religious, and communicative purposes.

Nowadays, engraving has also been applied to metal and has become an important process of metal processing. This article will analyze several common processes of metal engraving, commonly used metal raw materials, and the advantages of metal engraving.

Common metal engraving methods

1.Traditional scratch engraving

This process uses a non-rotating tool with a tapered diamond tip. Drag the engraving tool across the metal part to leave an impression. Diamond drag enables high quality and precise engraving compared to hand engraving. The width of the stroke is constant and the depth does not vary. Diamond drag knives are recommended for soft metals and are ideal for engraving jewelry and trophies.

The advantages of this method are that it is usually the fastest form of engraving, as well as the cheapest, and the width of the strokes allows for the engraving of small letters. One drawback is its limited stroke width.

2.Burnishing

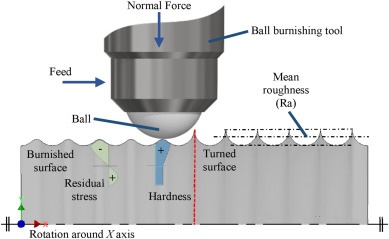

Polishing uses a limited pressure rotary tool. The tool, which can be a carbide tool or a diamond tool with varying tip widths, removes top coatings or layers of material and creates a smooth, polished surface. Polishing can replace the use of diamond drag. Polishing is still a newer process for many shops.The benefit of polish is that virtually unlimited stroke widths and greater letter heights can be achieved. Some disadvantages are that it is more expensive and requires a noisier engraving motor and additional polishing adapters.

3.Rotary Engraving

This method uses a single or multiple flute cutting tool that is rotated through the metal part to remove material, leaving an exposed core of the flute. It can result in deeper cuts or complete cutting of letters or objects. In most applications, the spindle micrometer setting controls the depth of cut. This process is suitable for most commercial and industrial jobs.

Rotary engraving is the most permanent form of engraving and can create letters of almost any size and can achieve both two- and three-dimensional looks. Some disadvantages are that it requires more cutting tools, rotating spindles, and motor options, and generally requires more cleanup.

4.Laser Beam Engraving

Laser engraving machines can cut, engrave or mark metal materials. The laser beam physically removes the metal surface, creating a cavity that displays an image at eye level. The laser beam generates high heat in the process, which essentially causes the material to evaporate.

Common metal materials

Bright coated or anodized aluminum is used to create plaques or trophy boards. Process-grade aluminum is used to construct control panels, interior and exterior signage, and industrial applications. This metal can have a less stable surface than brass, copper, and bronze when it comes to cutting difficulty. However, almost any aluminum alloy can be cut with some experimentation and patience.

2.Stainless Steel

Stainless steel is more difficult to engrave, but due to it has many advantages, sometime manufacturers will chose it to process. It is extremely durable, resistant to corrosion, moisture, and will not stain other materials. It is used in food processing plants and hospitals, where reaction or corrosion can destroy most metals. Other applications include containers, control panels, switch and legend boards, signs and elevator panels.

The collet spindle is one of the most important tools when cutting stainless steel. The chuck spindle with split chuck grips cutting tools close to the work area. This extra rigidity will allow for deeper cuts and less knife chipping or breakage. And need to attention laser engraving cannot be used on steel because the heat generated by the laser removes important protective layers, but laser annealing can.

3.Gold, Silver, Pewter

These metals are soft and cut easily. They are suitable for gift items in most engraving applications, such as jewelry personalization, with diamond drag engraving being the preferred method. These materials can be easily cut deep using the same cutting tools as brass. In most cases, cutting fluid is not required.

Features of laser engraving

The advantages of laser engraving are that the high precision and quality it provides allows for more detailed images and sharper cuts, it is faster, it is a more affordable option compared to CNC machines, and it does not produce waste such as sawdust. The disadvantages are that thicker materials are more difficult to laser cut or require very slow speeds, and the laser can burn the edges of any material being cut. Laser engraving machines also use a lot of energy, increasing production costs.

Summary

Metal engraving technology can be used to provide permanent part markings and labels for products in various industries. We hope this guide gives you a better understanding of the metal engraving methods available and the different materials they are suitable for.

Do you have a project that includes engraving services or any other type of part marking? Contact us for a free, no-obligation quote.

Post time: May-27-2024