Overmolding is a special injection technology for custom, at now overmolding improve functionality, performance, and exterior of products, which make it become more popular with manufacturers of consumer products, medical devices, and portable devices.

But what's overmoldind and when manufacturers will use this technology. This article will Introduce to you in detail.

What’s overmolding

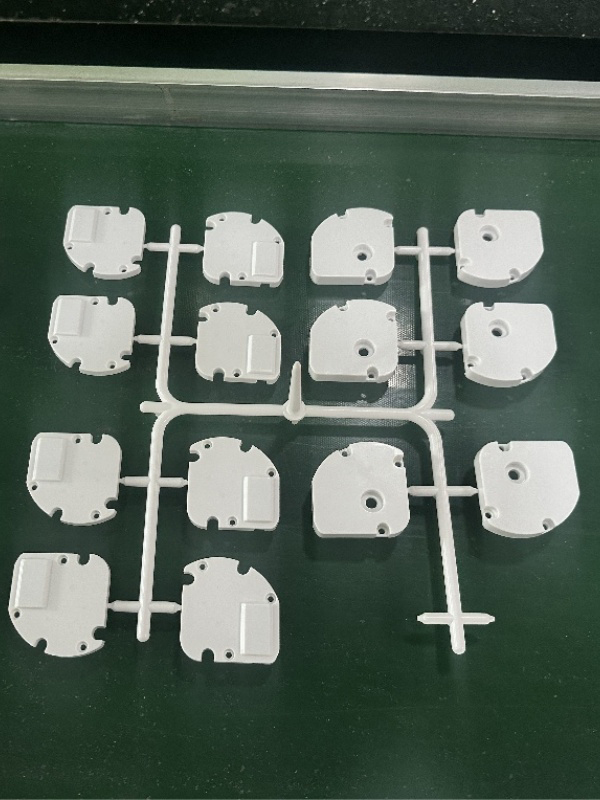

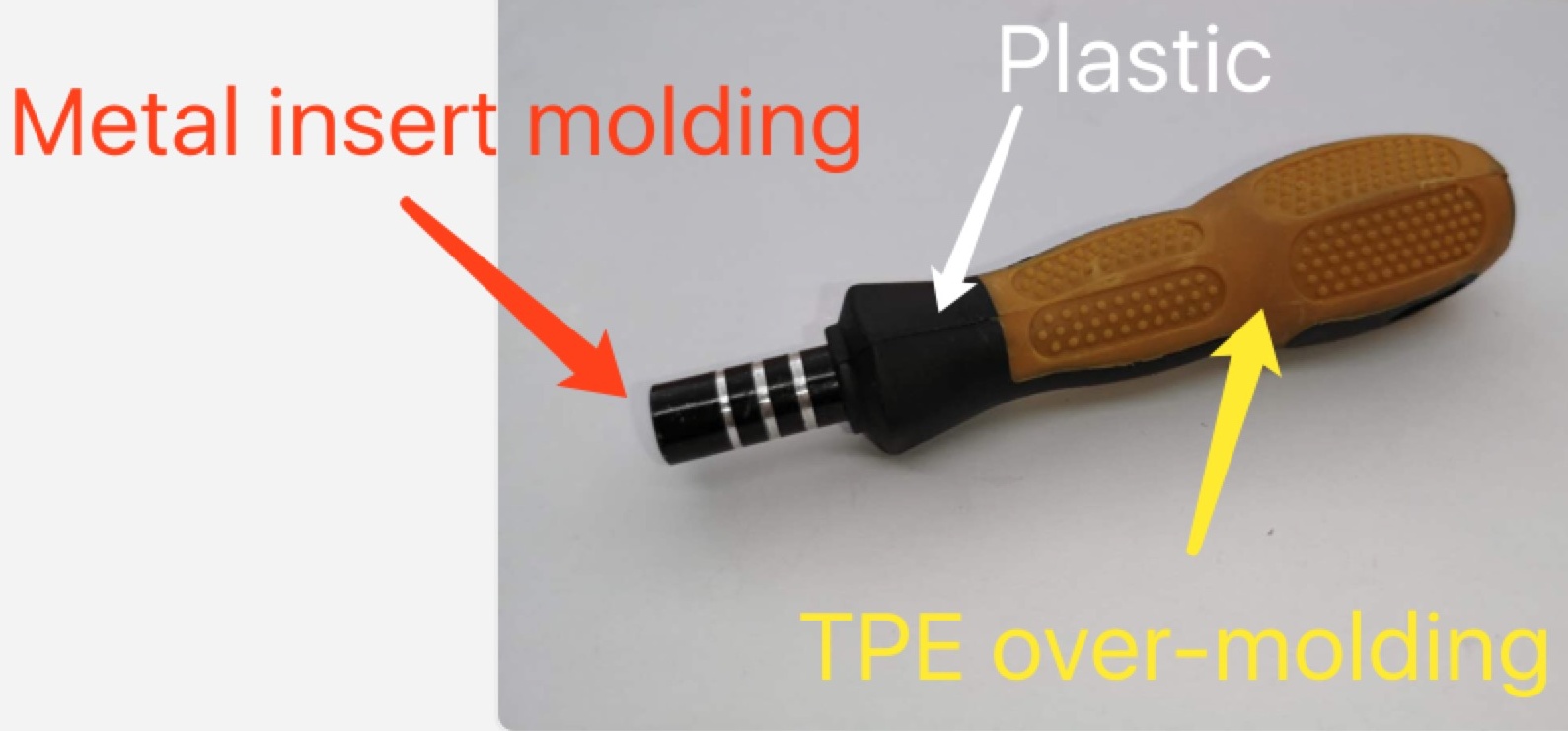

Overmolding is a injection molding process, which allow to add other material to existing product, that's make it can provide a combination of characteristics that no single material can provide and it can seamless combination of multiple materials into a single part or product.

As a manufacturing process, overmolding can provide excellent adhesion between different materials and totally made by machine, it can be quite cost-effective. And due to this reason, overmolding can help reduce costs and accelerate products making. But the most important, it can enhance the possibilities of combinations between different materials, make designer can show more characteristics in a product.

There are two primary methods for overmolding—two-shot molding and pick-n-place molding, with the former using a single production mold while the latter uses two molds.

When can this technology be used?

Manufacturers use overmolding and to produce products for a wide range of industries. Here are some examples of products in Various industries.

Overmolding is used to create solid two-tone interior components in automotive industry, such as door and dash panels, handles, knobs, and various controls.

Look around your home, and you’re likely to spot more than a few plastic objects that are one solid piece made up of multiple colors. You can bet that many of those products were manufactured using overmolding. This popular manufacturing process is used to make everything from Speaker Housing Box,Cover to storage bins and plastic containers.

The medical industry relies heavily on overmolded parts because plastics are easier to sterilize than electrical.such as:Tube Box, Transparent Plastic Injection Tube often be made by overmolding,that's make they have many characteristics and colors to suit any daily requirement.

4.Electrical Industry

Electrical wires are made safer and, in certain cases, weatherproof by insert molding a rubber exterior. Manufacturers often coat wiring components in rubber to make products, like cellphone and computer chargers, safer for consumers. Sometimes, multiple wires are encased in one layer of rubber, and other times, wires are separated out and differentiated using contrasting colors, like blue and red.

What can this technology do

Add a soft-touch exterior to products

• Enhance grip or “feel”

• Provide a stylish appearance that’s attractive to consumers

• Reduce shock and vibration

• Dampen sound

• Provide electrical insulation

• Improve chemical/UV resistance

• Increase product longevity

If you have any upcoming projects for overmolding and need this technology. Please contact us! We can provide professional technology for overmolding to help you.

Post time: Mar-18-2024