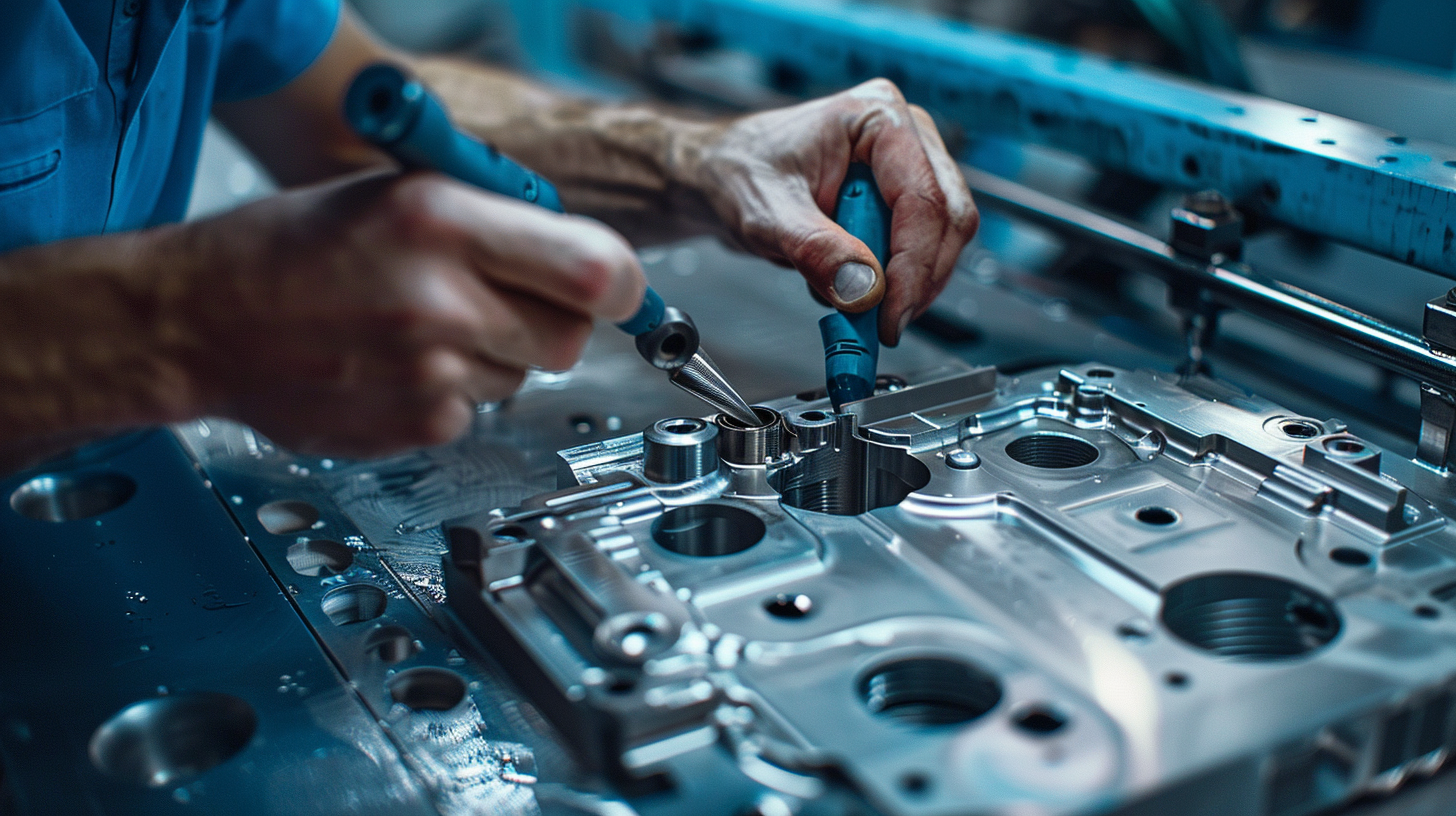

Injection molds are crucial in the manufacturing process, especially for producing precise plastic parts. The durability and lifespan of these molds directly affect production efficiency and costs. A well-maintained mold can produce hundreds of thousands of parts, making mold life a critical factor for manufacturers.

Factors Affecting Mold Life

Several factors impact the lifespan of injection molds:

1.Material Quality: High-quality steel molds last longer and resist wear better than those made from softer materials. At our company, we use premium-grade steel to ensure mold longevity and durability.

2.Design and Engineering: Proper design ensures even stress distribution and includes features like cooling channels to prolong mold life. Our experienced design team provides optimized solutions to enhance mold performance.

3.Processing Parameters: Optimized injection pressure, temperature, and cycle times prevent excessive wear. Our advanced injection molding equipment allows precise control over these parameters, ensuring optimal mold operation.

Type of Plastic Resin: The abrasiveness and corrosiveness of the plastic resin used can affect mold longevity. Some resins cause more wear than others. We select appropriate resin materials based on production needs to minimize mold wear.

Maintenance Tips

Maintaining molds involves:

1.Regular Inspections: Early detection of issues like cracks or corrosion prevents major problems. We have a systematic inspection process to ensure each mold remains in top condition.

2.Proper Cleaning: Use appropriate cleaning agents to remove residues without damaging the mold. Our professional cleaning equipment and agents ensure safe and effective mold cleaning.

3.Lubrication: Proper lubrication of moving parts reduces friction and wear. We use high-quality lubricants to ensure smooth mold operation.

Storage Conditions: Store molds in clean, dry environments to prevent rust and corrosion. Our strictly controlled warehouse environment ensures molds are protected from environmental factors.

Industry Standards

We strictly adhere to international standards such as ISO 9001, ensuring efficient manufacturing processes, including mold maintenance and quality control. Regular calibration of injection molding machines helps maintain proper operational parameters, reducing the risk of mold damage.

Conclusion

Maintaining injection molds is vital for efficient and cost-effective production. Understanding the factors that affect mold life and implementing robust maintenance practices can maximize mold lifespan and ensure high-quality part production. With high-quality materials, a professional design team, advanced equipment, and strict quality control, our company provides the most reliable injection mold solutions to help our clients achieve their production goals. If you have any project needs, please feel free to contact us, we will be on call 24 hours a day

Post time: Jul-01-2024