Extrusion is a fundamental manufacturing process widely used in both the plastics and metals industries. This technique involves forcing material through a shaped die to produce continuous profiles with consistent cross-sections. It's a highly efficient and versatile process, enabling the production of a wide range of products, from simple to complex shapes.

What is Extrusion?

Extrusion is a process where a material, often in the form of pellets or powder, is heated until it becomes malleable and is then forced through a die to create a continuous shape. The material is pushed by a screw or ram, depending on whether the extrusion is continuous or semi-continuous. The die determines the shape of the final product, and after exiting the die, the material is cooled and solidified.

Types of Extrusion

Extrusion can be categorized into several types depending on the material and the final product's application:

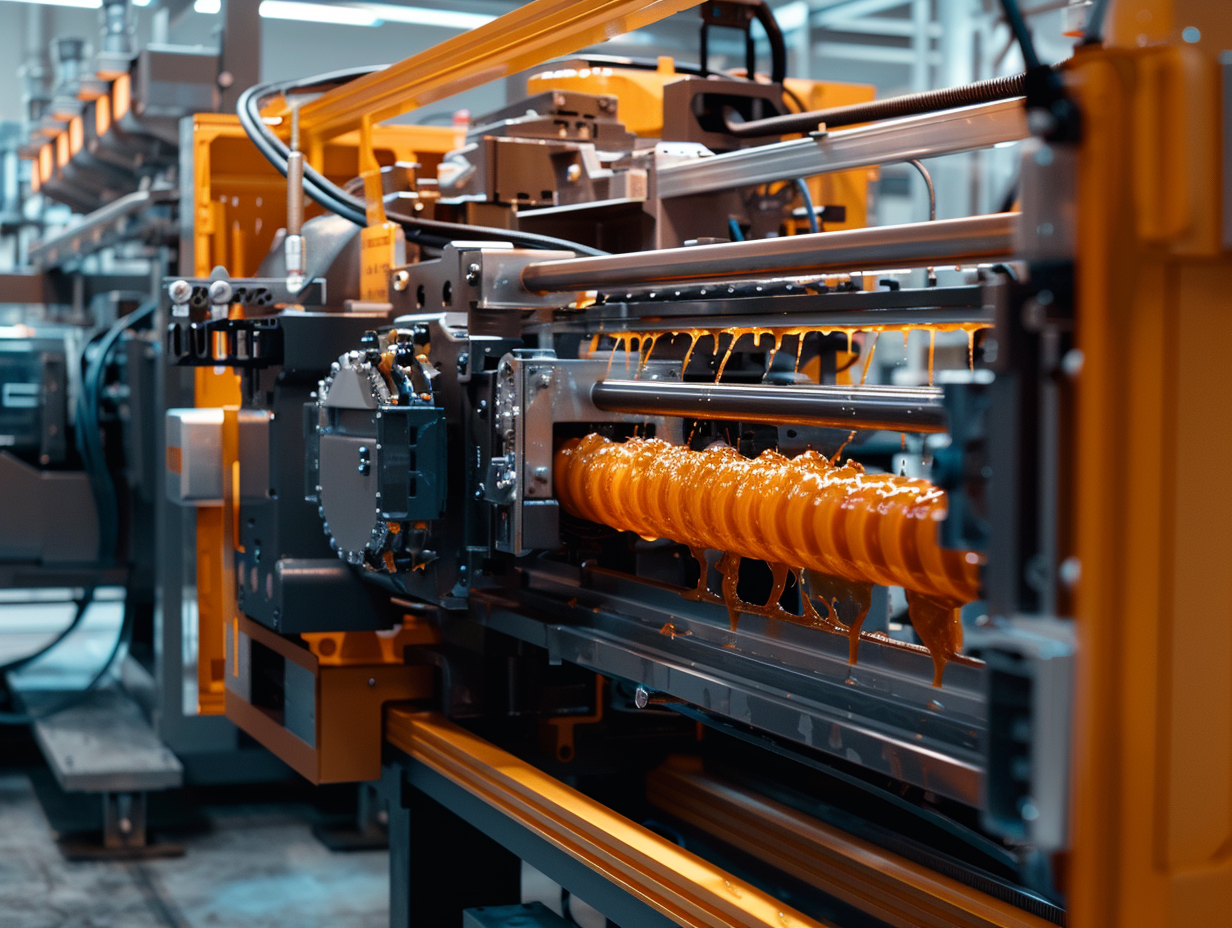

Plastic Extrusion

In plastic extrusion, thermoplastic materials like ABS, polyethylene, and polypropylene are commonly used. These materials are melted and forced through a die to form products like pipes, sheets, and films. The versatility of this process allows for the production of both flexible and rigid products, depending on the material and processing conditions.

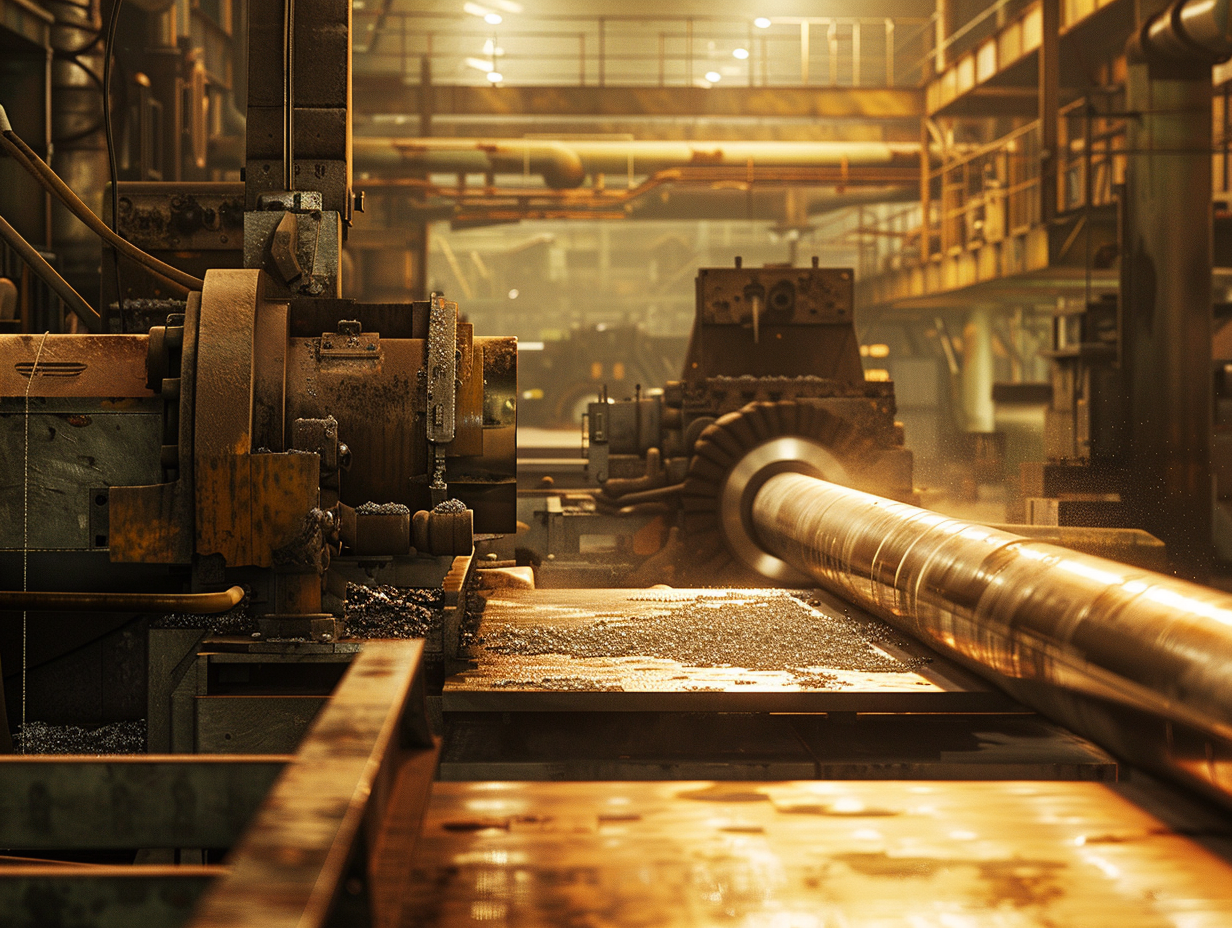

Metal Extrusion

Metal extrusion involves pushing heated metal, such as aluminum, copper, or steel, through a die to create rods, tubes, and complex profiles. This process is essential in the automotive, aerospace, and construction industries, where precision and durability are paramount. Unlike plastic extrusion, metal extrusion often requires higher temperatures and pressures.

Applications of Extrusion

Extrusion has a wide array of applications in different industries, each leveraging the process's ability to create complex shapes and profiles efficiently.

Plastic Applications:

1.Pipes and Tubing: One of the most common applications of plastic extrusion is in the production of pipes and tubing. Polyvinyl chloride (PVC) and polyethylene are often used due to their durability and flexibility.

2.Films and Sheets: Extruded films and sheets are used in packaging, construction, and automotive industries. Polyethylene terephthalate (PET) is a popular material for these applications due to its strength and clarity.

3.Profiles and Channels: Custom profiles, such as window frames and weatherstripping, are often extruded from PVC and other rigid plastics.

Metal Applications:

1.Aluminum Profiles: Aluminum extrusion is widely used in the construction of window frames, heat sinks, and structural components due to aluminum’s light weight and corrosion resistance.

2.Copper Tubing: Extruded copper tubing is essential in plumbing and refrigeration systems for its excellent thermal conductivity.

3.Steel Rods: Extruded steel rods are used in construction and manufacturing for their strength and durability.

Our Expertise in Extrusion

At Ruicheng, we specialize in providing high-quality extrusion services for both plastics and metals. With years of experience in the industry, our team is equipped with the latest technology to meet the most demanding requirements.

Advanced Equipment: Our state-of-the-art extrusion machines allow us to produce complex profiles with high precision. Whether you need a custom plastic profile or a durable metal component, we have the tools and expertise to deliver.

Comprehensive Services: From initial design consultation to final production, we offer a full range of services to support your extrusion needs. Our in-house engineering team works closely with clients to ensure that every project meets the highest standards of quality and efficiency.

Quality Assurance: We adhere to strict quality control procedures at every stage of the extrusion process. This commitment to quality ensures that our products not only meet but exceed industry standards.

Why Choose Us?

Choosing Ruicheng for your extrusion needs means partnering with a company that values quality, precision, and customer satisfaction. Our extrusion services are designed to help you bring your ideas to life, whether you're looking to produce a simple plastic profile or a complex metal component.

If you're interested in learning more about how our extrusion technology can benefit your next project, feel free to contact us today. Our team is ready to provide you with the solutions you need to succeed.

Post time: Aug-19-2024