Ultrasonic welding is a joining process that uses high-frequency mechanical vibrations to join two or more pieces of materials together. This process is commonly used in manufacturing to join plastics and plastic, as well as other materials.

Ultrasonic welding has several advantages over other welding methods. For example, it can be used to join dissimilar materials, it produces a strong and consistent bond, and it can be completed quickly and without the need for additional materials like adhesives or fasteners.Applications of ultrasonic welding can be found in a wide range of industries, including automotive , electronics, medical devices, and consumer goods .

Here are the general steps for performing ultrasonic welding between plastic parts:

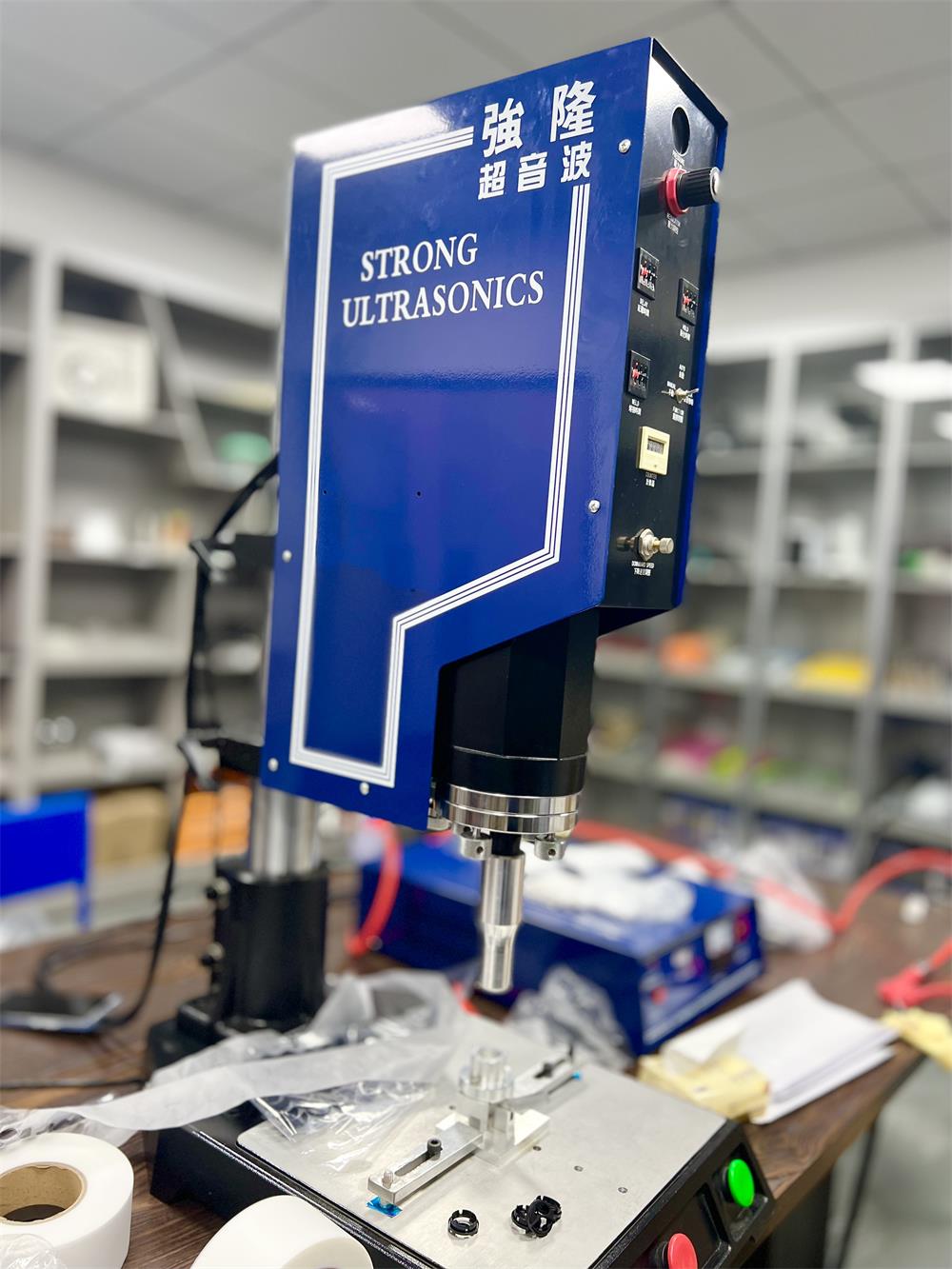

Choose the right equipment: You will need an ultrasonic welding machine that is capable of generating the required frequency and amplitude to weld your specific materials. Make sure you have the right horn (also called a sonotrode) and fixture to hold your parts in place during the welding process.

Prepare the parts: The surfaces of the plastic parts to be welded should be clean and free of any dirt, grease, or other contaminants that could affect the weld quality. Additionally, the parts should be positioned in the fixture with the correct orientation and alignment for welding.

Apply pressure: The fixture holding the plastic parts should be clamped securely to ensure that the parts remain in position during the welding process.

Apply ultrasonic energy: The ultrasonic horn is then lowered onto the parts and pressure is applied. Ultrasonic energy is then applied to the plastic parts, causing the material to melt and fuse together. The duration of the ultrasonic energy application will depend on the size and type of plastic parts being welded.

Allow to cool: Once the welding is complete, the ultrasonic horn is lifted, and the welded assembly is allowed to cool down for a short time. This cooling process helps to ensure that the weld remains strong and secure.

Overall, ultrasonic welding is a highly effective method for joining plastic parts, and with proper equipment and techniques, it can produce strong, durable welds. However, it's important to note that the success of the welding process will depend on a number of factors, including the type of plastic being welded, the equipment used, and the welding parameters. It is recommended to test the process on sample parts first to optimize the process and ensure a reliable and consistent weld quality.

Would you like to know more Ultrasonic welding? Contact us now!

Post time: Feb-16-2023