Introduction

Extrusion moulding is a pivotal process in modern manufacturing, enabling the creation of continuous shapes and profiles with precision and efficiency. This blog delves into the intricacies of extrusion moulds, exploring their history, applications, advantages, and the unique capabilities they bring to the table.

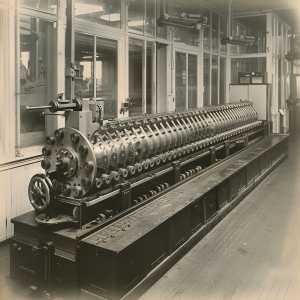

History of Extrusion Moulding

Extrusion moulding has a rich history dating back to the early 19th century. Initially used for producing lead pipes, the process evolved significantly with the advent of synthetic polymers in the 20th century. Today, extrusion moulding is indispensable in manufacturing a wide array of products, from simple plastic tubes to complex architectural profiles.

What is Extrusion Moulding?

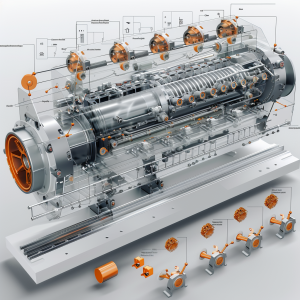

Extrusion moulding involves forcing molten material through a die to create long, continuous shapes with a uniform cross-section. The process is highly versatile, allowing for the production of profiles, tubes, sheets, and more, using materials such as plastics, metals, and ceramics.

The Extrusion Moulding Process

Material Feeding: Raw material, typically in the form of pellets or granules, is fed into the extruder.

Melting: The material is heated to a molten state as it moves through the heated barrel of the extruder.

Forming: The molten material is forced through a shaped die to create the desired profile.

Cooling: The extruded material is cooled and solidified as it exits the die.

Cutting and Finishing: The continuous extruded profile is cut to the required lengths and subjected to any necessary finishing processes.

Applications of Extrusion Moulding

Extrusion moulding is utilized in various industries due to its efficiency and ability to produce uniform products. Common applications include:

Construction Materials: Profiles for windows, doors, and insulation.

Packaging: Plastic films, sheets, and tubes.

Automotive Parts: Trim, seals, and gaskets.

Consumer Goods: Pipes, hoses, and cables.

Medical Devices: Tubing and catheters.

Conclusion

Extrusion moulding remains a cornerstone of modern manufacturing, offering unparalleled efficiency and versatility. Understanding the process, applications, and advantages of extrusion moulding can help businesses leverage this technology to enhance their production capabilities. Trust in our expertise to bring your designs to life with precision and excellence.

Post time: Jul-24-2024