In the world of modern product design and manufacturing, choosing the right materials is crucial for achieving the desired performance, durability, and aesthetics of the final product. Among the many combinations available, Polycarbonate (PC) + Thermoplastic Polyurethane (TPU) has become increasingly popular due to its versatile properties. Both materials offer unique advantages, making them an ideal pairing for a variety of applications, from consumer electronics to automotive components.

In this blog, we’ll explore the benefits of combining PC and TPU, the challenges faced during production, and how our expertise can help overcome those issues to deliver top-quality results.

Benefits of PC + TPU

Polycarbonate (PC) is known for its durability, impact resistance, and transparency. It’s widely used in products that require a strong yet lightweight material, such as protective covers, electronic enclosures, and automotive parts. PC offers excellent resistance to high temperatures, UV radiation, and physical stress, making it ideal for environments where strength and stability are critical.

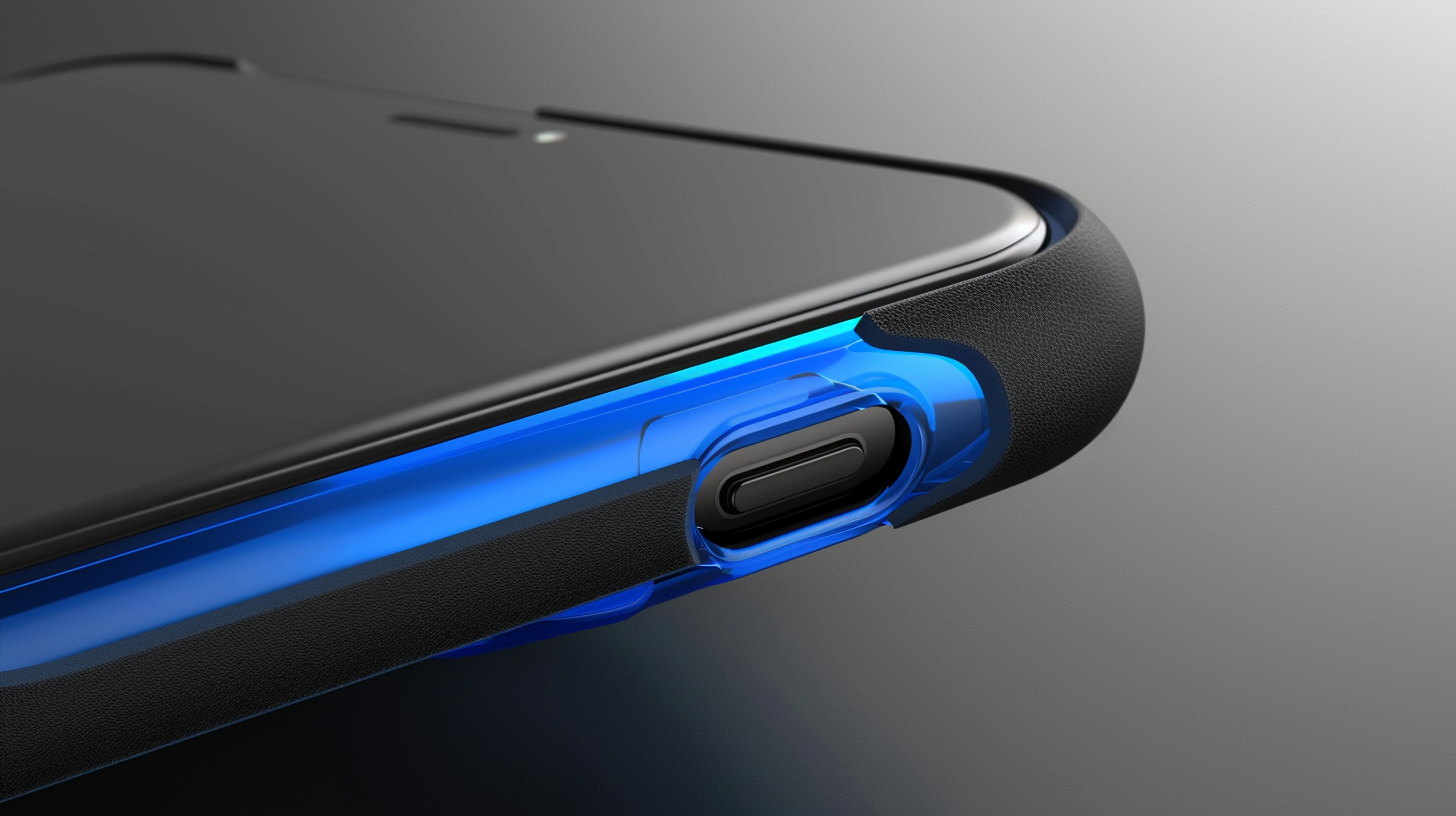

On the other hand, Thermoplastic Polyurethane (TPU) is a highly flexible, elastic material known for its excellent abrasion resistance and ability to withstand repeated wear and tear. TPU also provides a rubber-like texture, making it suitable for applications that require grip, cushioning, or flexibility. Its elasticity and flexibility allow it to absorb shocks, making it an ideal material for protective cases, seals, and gaskets.

When these two materials are combined—often in overmolding or co-molding applications—manufacturers can benefit from the best of both worlds: the rigidity and strength of PC and the flexibility and softness of TPU. This combination is frequently used in products such as smartphone cases, wearable technology, and automotive components, where a strong outer shell with a soft, impact-absorbing layer is needed.

Production Challenges of PC + TPU

While the combination of PC and TPU offers impressive advantages, there are several challenges during the manufacturing process that need to be addressed to ensure high-quality products. One of the main difficulties is ensuring proper bonding between the two materials. Since PC and TPU have different thermal properties, the injection molding process must be carefully controlled to avoid issues such as poor adhesion, warping, or surface defects.

Another common issue is temperature management. PC requires a higher processing temperature, while TPU is more sensitive to heat. If the temperature settings are not optimized during the molding process, this can lead to material degradation, poor surface finishes, or even delamination between the two layers.

Moreover, shrinkage rates between PC and TPU can vary significantly, causing problems with dimensional accuracy. If the materials cool at different rates, it can result in warping or misalignment of the final product, especially in applications where tight tolerances are required.

Surface finishing is also a potential challenge when using PC + TPU combinations. Achieving a smooth, consistent finish that meets aesthetic and functional requirements can be difficult, particularly when trying to maintain clarity or achieve specific textures. This is especially true in consumer electronics, where the appearance of the product is as important as its functionality.

How We Can Help Overcome These Challenges

At RuiCheng, we specialize in the precise molding of complex material combinations like PC and TPU. Our team has extensive experience in managing the unique properties of these materials and overcoming the challenges that arise during production. Here’s how we can help:

1.Optimized Molding Process: Our advanced molding technology ensures that the processing temperatures for both PC and TPU are carefully managed to prevent overheating, material degradation, or poor bonding. We use sophisticated molding techniques to guarantee strong adhesion between the two layers, resulting in a durable, high-performance product.

2.Dimensional Accuracy: We understand the importance of maintaining tight tolerances and preventing issues like warping or shrinkage. By using state-of-the-art equipment and monitoring tools, we ensure that both PC and TPU cool evenly, avoiding dimensional inaccuracies and delivering products that meet the highest standards of precision.

3.Surface Finishing Expertise: Whether your product requires a high-gloss finish, a matte texture, or specific visual effects, our team can deliver the perfect surface finish for your needs. We pay special attention to the aesthetic and functional requirements of your product, ensuring that the final result is not only visually appealing but also highly functional.

4.Customized Solutions: Every project is unique, and we work closely with our clients to develop customized solutions that meet their specific needs. Whether you’re working on consumer electronics, automotive parts, or medical devices, we’ll tailor our process to ensure the best possible results for your product.

Conclusion

Combining Polycarbonate (PC) and Thermoplastic Polyurethane (TPU) in manufacturing offers a range of benefits, including strength, flexibility, and durability. However, it also comes with its own set of challenges, from temperature management and bonding to shrinkage and surface finishing. At Ruicheng, we have the expertise and technology needed to overcome these challenges and produce high-quality products that meet your exact specifications.

If you’re looking for a reliable partner to help you manufacture products using PC + TPU, we’re here to help. Contact us today to discuss your project and learn how we can bring your designs to life with precision and efficiency.

Post time: Oct-09-2024