BLOG

-

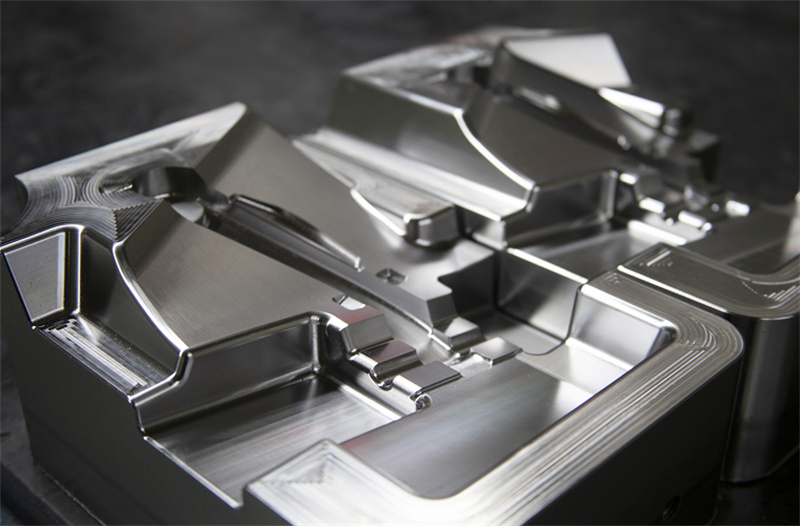

Do Plastic Injection Molds Wear Out or Have a Limited Production Life?

Plastic injection molds can wear out due to friction or repeated contact between parts over thousands of cycles. Wear primarily affects gates, slides, ejectors and other moving elements within the mold. When components slide or touch a...Read more -

Injection moulding surface finish design guide – DFM

Injection moulding surface finish as per SPI and VDI classification systems – Gloss, semi-gloss, matte and textured surface finish. Contents covered in this article What are Injection moulding surface finishes? Why use surface finishes in injection moulding? Injection ...Read more -

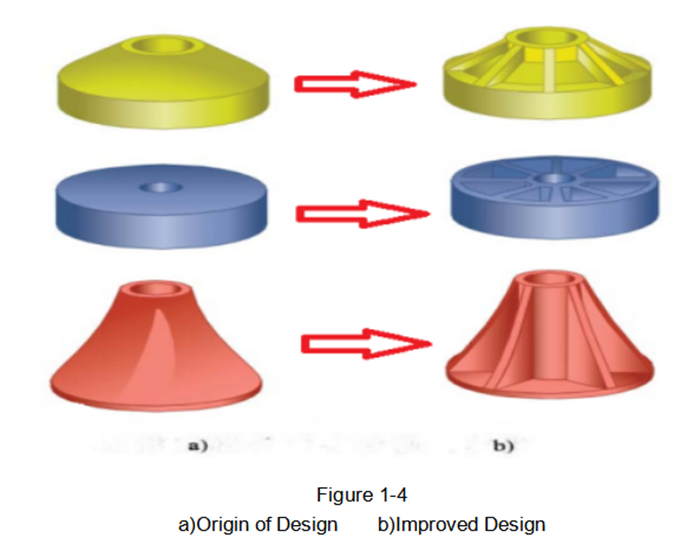

7 ways to reduce injection molding process

There are 7 ways to reduce injection molding costs, including: Optimize the design: A well-optimized design can help to reduce the amount of material used and lower the complexity of the molding process, thus reducing the cost of manufacturing. Choose the right material...Read more -

Ultrasonic Welding

Ultrasonic welding is a joining process that uses high-frequency mechanical vibrations to join two or more pieces of materials together. This process is commonly used in manufacturing to join plastics and plastic, as well as other materials. Ultrasonic welding has severa...Read more -

What is the relationship between plastic injection mold and shrinkage rate?

The relationship between plastic injection mold and shrinkage rate is complex and influenced by several factors, including: 1.Material type: Different plastics have different shrinkage rates, which can range from 0.5% to 2% which have a significant impact on the dimensional accuracy and quality o...Read more -

Why the plastic injected part is warpage deformation?

Warpage deformation refers to the distortion of the shape of the injection moulded product and warpage, deviating from the shape accuracy requirements of the part, it is one of the defects to solve in injection mould design and production. ...Read more -

Main Process Parameters Of Injection Plastic Parts

The main process parameters of injection molded parts can be grouped into 4 factors which include: Cylinder temperature, melt temperature, injection mold temperature, injection pressure. 1.Cylinder temperature: It is well-known that the success of plastic injection molded parts depends on many ...Read more -

TPE Overmolding

1.What is Overmolding Overmolding is a injection molding process where one material is molded into a second material. Here we mainly talk about TPE overmolding. TPE is called thermoplastic Elastomer, it is a functional material with both rubber elasticity and plastic sti...Read more -

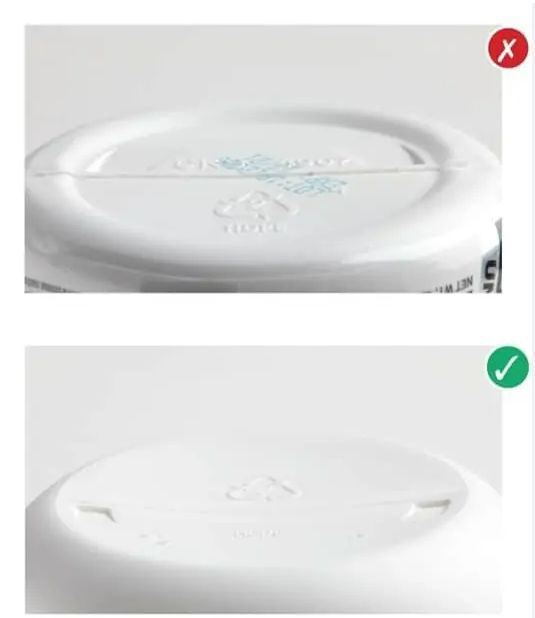

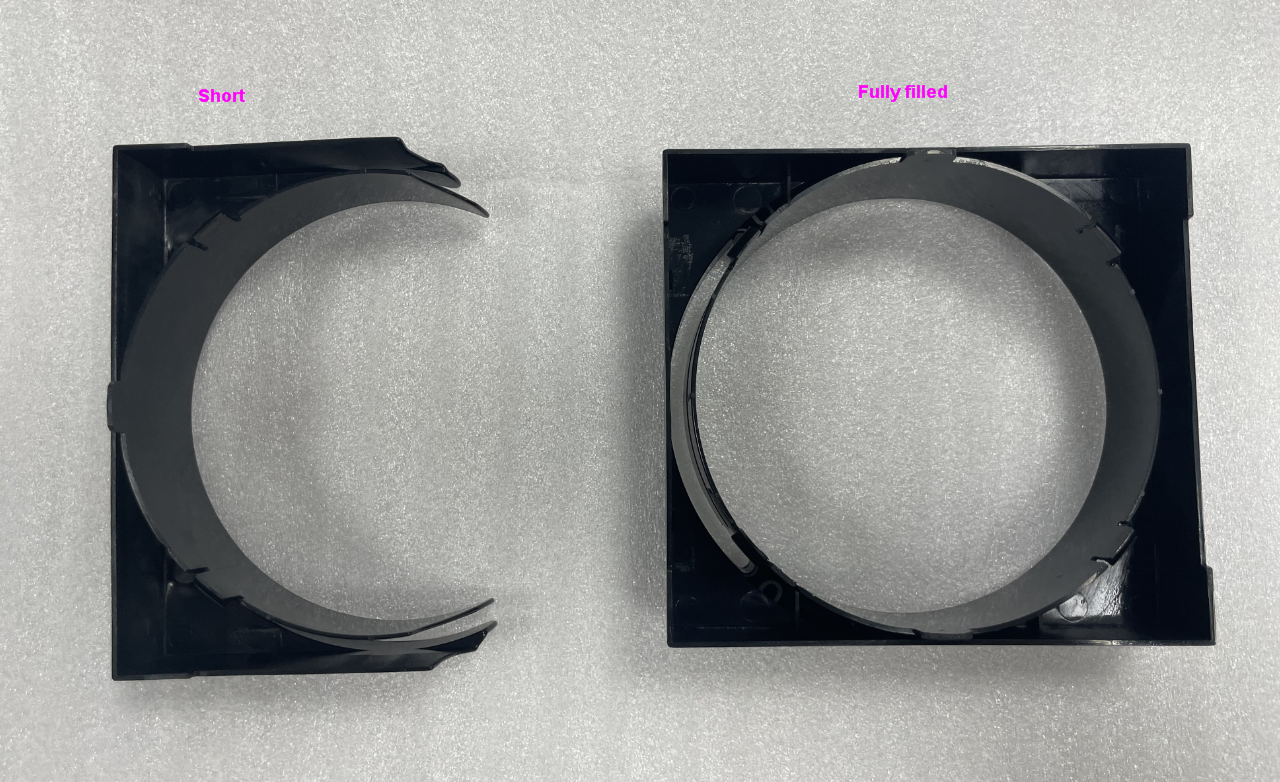

Why the plastic part is not fully injected?

In the injection molding, the short shot injection, also called underfill , refers to the injection plastic flow end of the phenomenon of partial incompleteness or a part of a mold cavity is not filled, especially the thin-walled area or the end of the flow path area. The performance of the melt...Read more -

Wall thickness design of injection molding plastic parts

In the design of plastic parts, the wall thickness of the part is the first parameter to be considered, the wall thickness of the part determines the mechanical properties of the part, the appearance of the part, the inject ability of the part and the cost of the part. I...Read more -

When to use rapid injection mould

apid injection moulding is a versatile technology that can be used to produce a wide variety of parts and products. The process is fast and efficient, and can be used to produce parts with complex geometries. Rapid injection moulding is also an ideal solution for prototy...Read more -

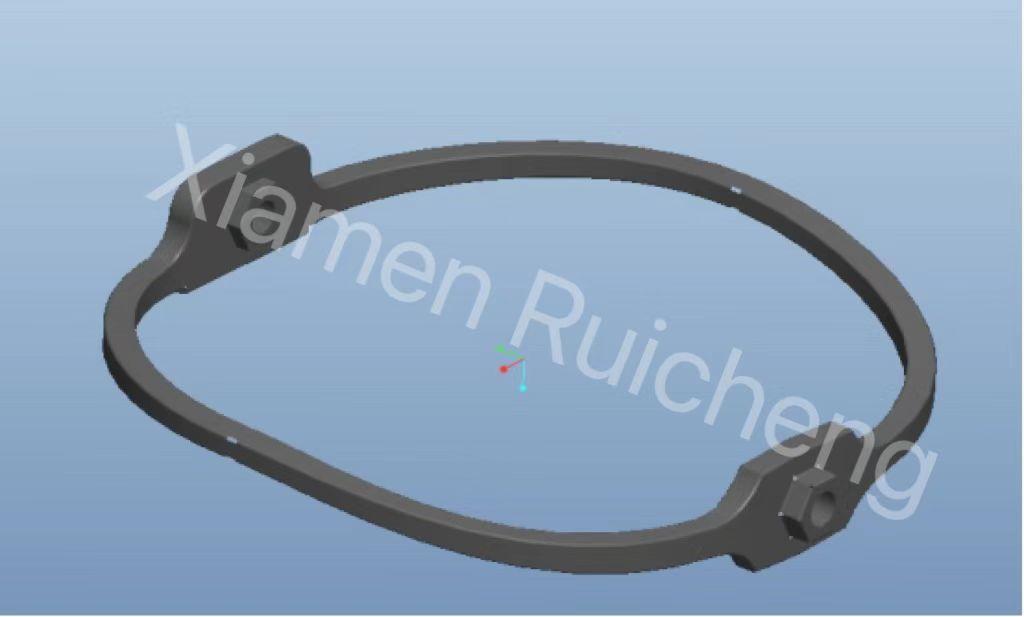

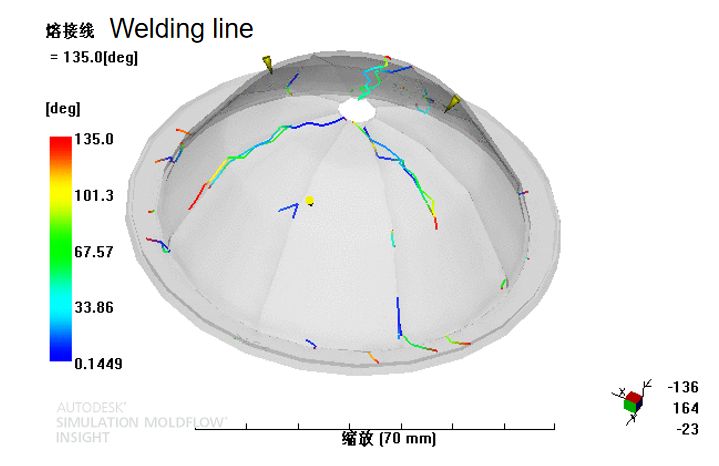

Plastic injection parts-welding line

What is a welding line Welding line is also called welding mark, flow mark. In the injection molding process, when multiple gates are used or holes exist in the cavity,or inserts and products with large changes in thickness dimensions, the flow of plastic melt occurs in the mold in more than 2 di...Read more