Nylon Injection Molding Parts for Transformer

Product Details

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Top Grade Nylon Cap and Nylon Injection Molding Parts for Transformer, Welcome buddies from all over the earth come to visit, tutorial and negotiate.

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for China Nylon Injection Molding Parts for Transformer and Precision Nylon/ Plastic Parts Injection Mold, Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don't hesitate to contact us. We will do our best to meet your needs.

Before Mould-Making

After having the design 3D drawings, we will make a thorough analysis to evaluate its mould-making method based on your requirements, to find if the design needs any improvement for better production to avoid shrinkage/undercut/etc problems.

The following information is requested before mould-making:

1. Parts Design Drawing, better in 3D drawing, if not, 1pcs sample is acceptable;

2. Specified plastic material, or we can suggest the suitable material after knowing its usage conditions.

3. Estimate Production quantities

Mould-Making Process

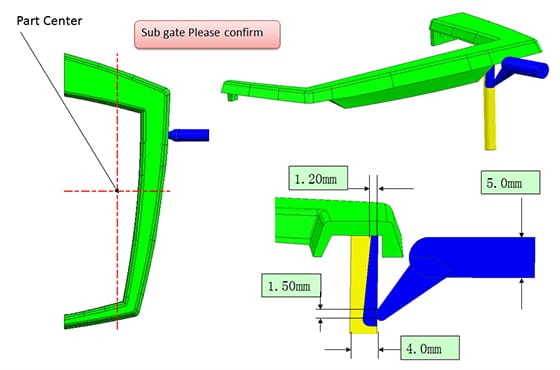

1.Mould DFM Analysis

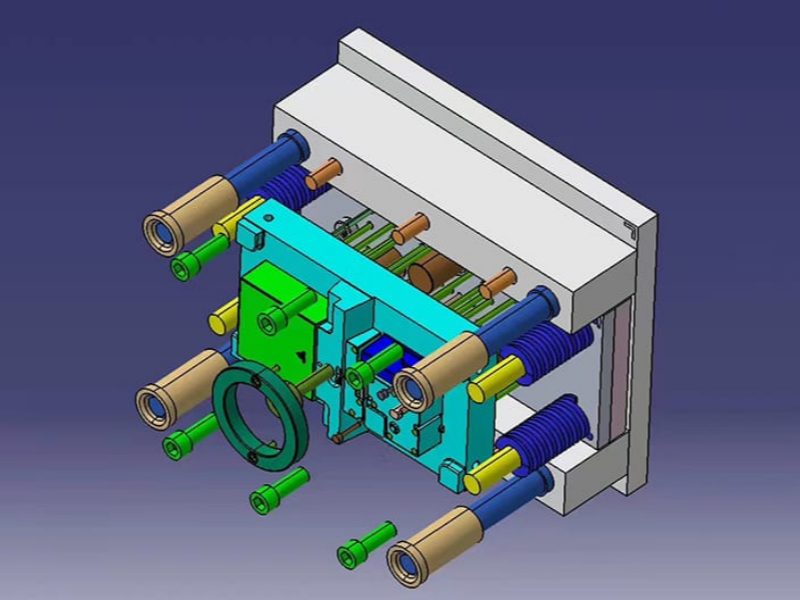

2.Mould Design

3.Mould Material Preparation

4.CNC Machining

5.EDM Machining

6.Grinding&Drilling Machining

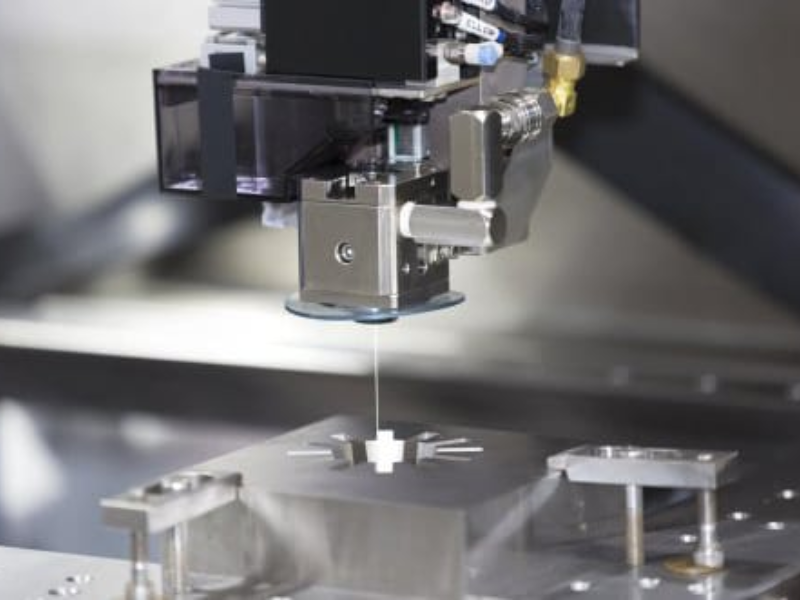

7.Wire EDM Maching

8.Mould Aftet Treatment

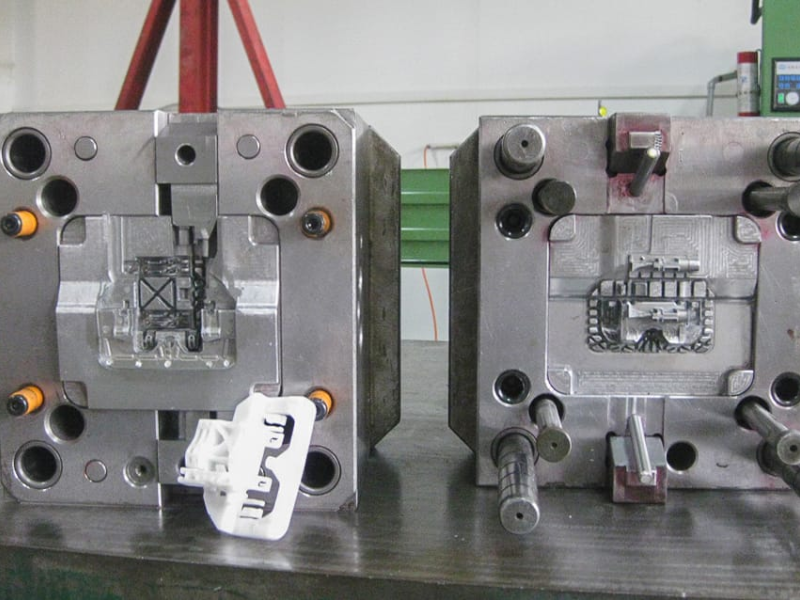

9.Mould Assembly