Where are plastic parts used?

Plastic injection products are found everywhere. From Automotive, Industrial ,Sports,Medical,household to Consumer Field,etc.

1000+ Die Casting Tooling Manufacturing Experience

➢ Superior design flexibility

➢ A wide range of materials

➢ Excellent visual appearance.

➢ Faster manufacturing times

➢ Great repeatability and tolerances

Injection molding processes

Rapid injection mould with quick lead times, ideal for prototyping and small quantity production that is for design validation to bridge production.

Overmolding

The overmolding process let you combine multiple materials into one part. One material, usually a thermoplastic elastomer (TPE/TPV/TPU) is molded onto a second material which is often a rigid plastic. Or to overmould metal inserts inside the plastics.

Two-color mold

Two-color injection molding is a manufacturing process used when referring to mold two materials/colors into one plastic part,which is a technology blends two materials or two different colors into one ending plastic part by using 2k injection molding machine.

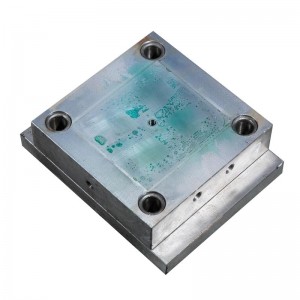

Mass production injection mold

Mass production Injection mold is a manufacturing process that involves injecting molten material into a mold cavity by using production grade steel mould material that can make its shot life to be more than 200,000cycles.

How it works

In house injection molding shop to meet variable project demands without any delays.

Send us your detailed plastic injection parts request now !

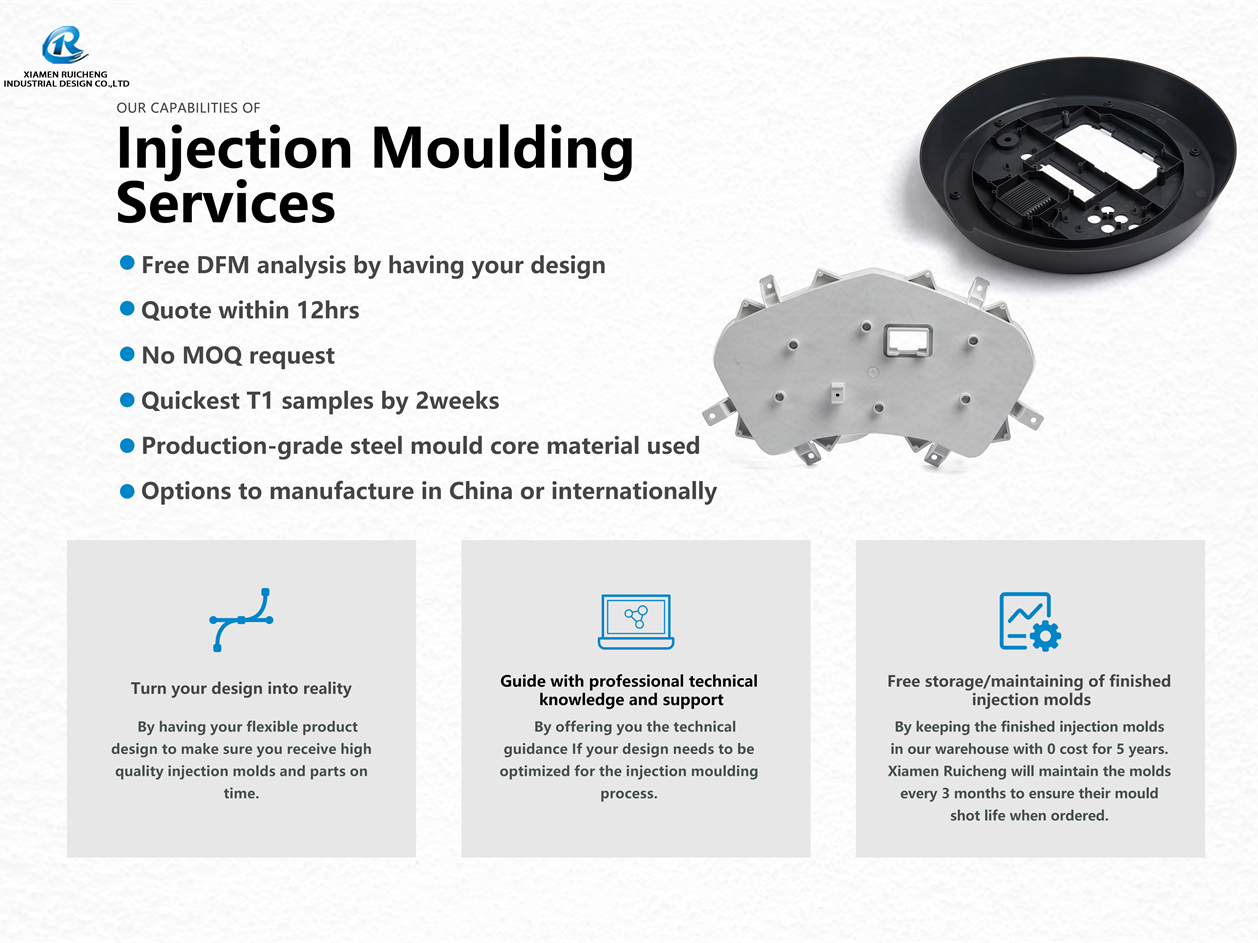

➢ Send your design of 3D CAD and technical drawings to our sales

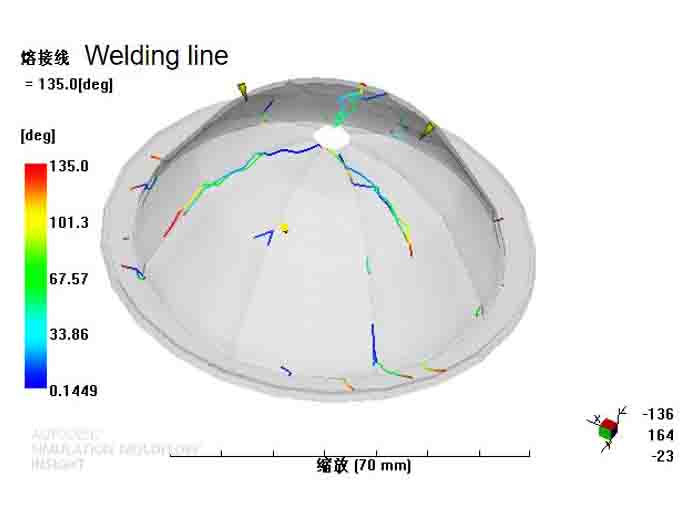

➢ Quotation will be offered with 12hrs,following free DFM report if necessary

➢ T1 samples will be delivered in 2-4 weeks for evaluation and testing to kick off production parts

➢ Once the T-final samples are approved ,it takes 5-10 days to finish the production

➢ Easily release the repeat order from your injection mould on demand