How to Fabricate a Rapid Sheet Metal

Working Process:

Sheet metal prototype forming refers to a set of manufacturing processes that are used to convert sheet metal into functional parts, including the process of bending, welding, cutting etc. The thickness is in the range of 0.015-0.635cm and the distinctive feature is the same thickness of same part.

The Main Materials

The commonly used metal plates are hot rolled plate, cold rolled plate, galvanized plate, copper plate, aluminum plate and stainless steel plate.

Sheet Metal Bending Service

Sheet Metal Bending Service

Sheet metal bending is a manufacturing process used commonly in sheet metal fabrication. By applying force to a sheet metal to overcome its ductility, causing the metal to physically deform without breaking or failing, create functional bending parts with V-shape, U-shape or more complex structure,such as motor shell, bracket,etc.

Metal Welding Fabrication

Sheet metal welding is welding multiple parts together or welding the edge seam of a single part to obtain a strong strength and a complete assembled metal part, usually used in metal cabinets, enclosure pipeline etc, with advantages of low production cost and compatibility of various materials.

Laser Cutting Service

Laser cutting is a process using a laser to vaporize materials, resulting in a cut edge, which with high accuracy and exceptional reliability. It is one of the indispensable processes in the sheet metal fabrication technology and It is almost impossible to create things out of metal sheets without cutting them.

Custom Sheet Metal Surface Treatment

We offer complete custom sheet metal fabrication services, with a wide range of surface treatments to improve the application performance and aesthetics of your material, You can select the best finish based on your needs and the characteristics of the material you use.

✧ Sandblasting

✧ Galvanizing

✧ Chrome plating

✧ Printing

✧ Brushing

✧ Power coating

✧ Anodizing

✧ Electroplating

✧ Mirror polishing

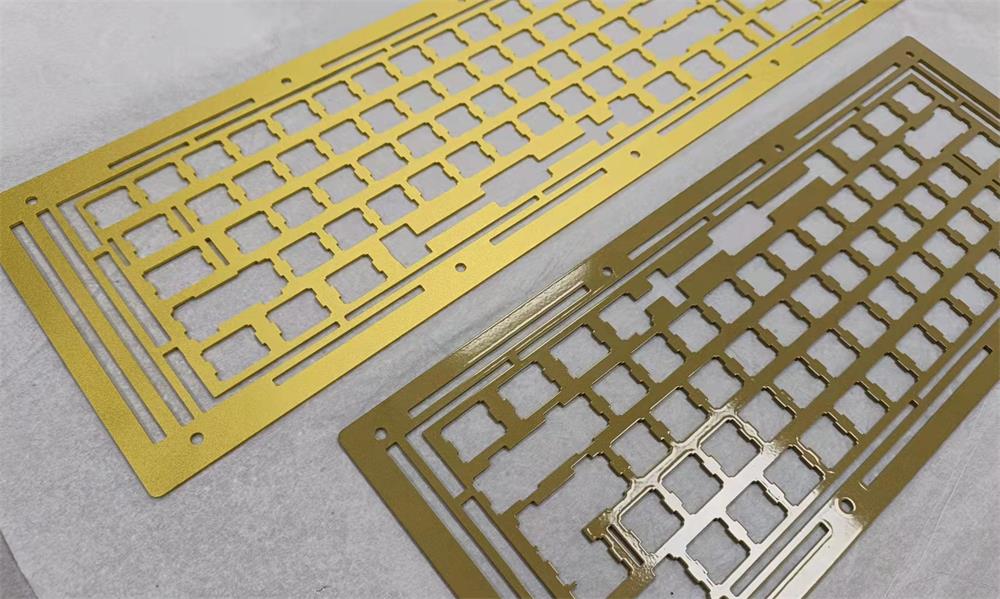

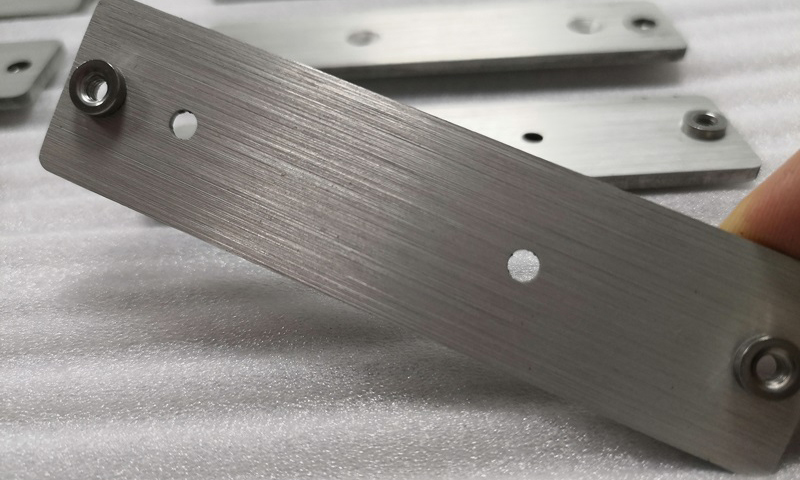

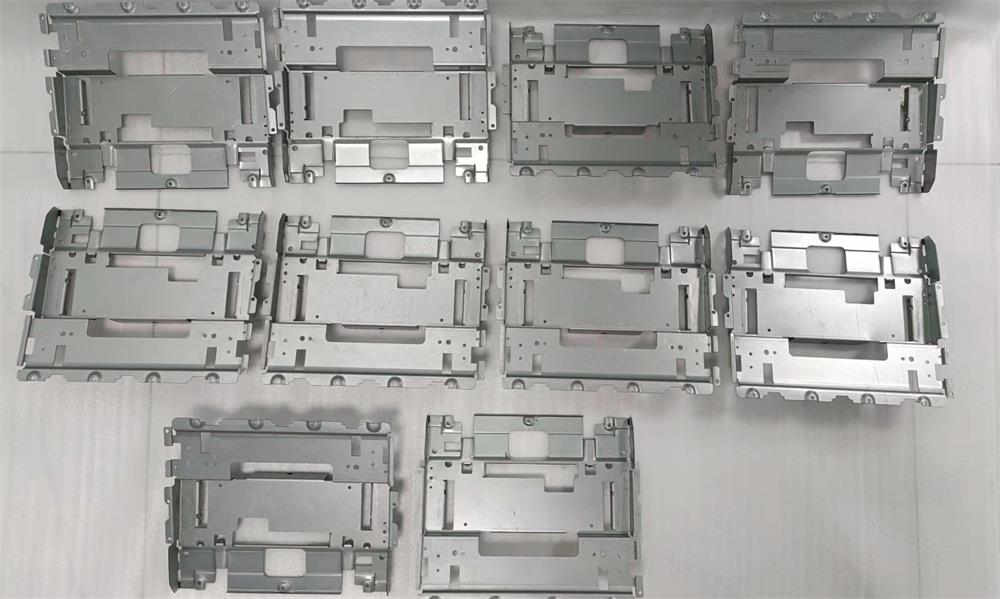

Sample Exhibition

Sheet Metal Prototype

Aluminum Chassis shell with black anodizing

Keyboard aluminum with paint

Sheet metal electrical enclosure with print finishing

Stainless steel plate in brushing finishing with pressnut

SPCC with natural polishing

SPCC with white powder coat